Combined with new materials and updated features, the UltiMaker S8 provides a versatile 3D printing solution.

UltiMaker has announced the launch of the UltiMaker S8 3D printer, designed to enhance productivity while ensuring precision, security, and reliability.

The UltiMaker S8 was engineered for productivity, capable of speeds up to 500mm/s and accelerations up to 50,000mm/s2. Equipped with features like the new UltiMaker Cheetah motion planner, high flow print cores, and an improved feeder system, the UltiMaker S8 can deliver up to 4x the productivity of its predecessor, the S7. The new printer produces parts more quickly while maintaining quality, supporting businesses with tight production schedules.

The UltiMaker S8 is built for industrial and engineering applications, capable of printing durable and precise components using industrial-grade materials. The S8 supports dual extrusion, allowing users to create complex parts with multiple materials in a single print job. The S8 is compatible with UltiMaker’s wide range of materials in the UltiMaker Marketplace, which offers over 300 materials to choose from, including the new UltiMaker Nylon CF Slide, a copolymer offering wear resistance, temperature resistance of up to 180°C, and PFAS-free performance.

Now available is Cura Cloud on UltiMaker Digital Factory, the new cloud slicer powered by UltiMaker Cura. Digital Factory was designed to streamline every step of the 3D printing process, and, with Cura Cloud, users can slice, manage, and print all from one platform. Cura Cloud introduces a feature designed to streamline workflow and improve process efficiency. Digital Factory offers various subscription plans tailored to different production requirements. The S8 is designed to accommodate both prototyping and production-ready component manufacturing.

Key features of the UltiMaker S8 include:

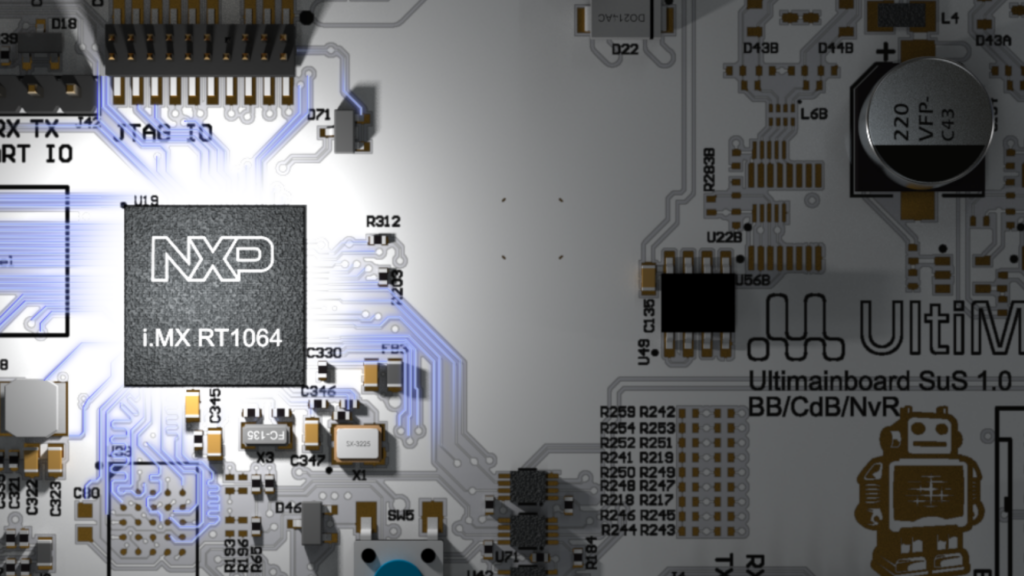

Increased productivity and improved print quality: The UltiMaker S8 features an upgraded electronics platform with up to five times the processing power of the S7. UltiMaker Cheetah enhances motion control, resulting in precision of 0.15mm ± 0.15% and eliminating issues such as ringing, blobs, and mechanical stress which typically occurs at high speeds. UltiMaker Cheetah enables the S8 to achieve up to 4x faster print speeds than its predecessor, for high-performance production timelines. The S8 introduces hot-swappable AA+ and CC+ print cores, designed for high-flow to match the printer’s increased speed. The new cores deliver 2.5x more flow, improving efficiency and quality in composite and engineering-grade material printing. The hardened feeder module enhances material control for more consistent extrusion, supporting stable operation at high speeds. It improves the printer’s ability to handle various materials while maintaining print consistency.

Seamless UltiMaker ecosystem integration: The S8 connects with Digital Factory to streamline workflow management. Digital Factory allows users to manage their print jobs easily and securely from anywhere. With preset and custom subscription options for users, from individuals to global organizations, Digital Factory helps streamline 3D printing workflows and collaboration across teams and time zones. The expansion of Cura from desktop to the cloud takes the powerful slicer and makes it accessible to all Digital Factory users. The Cura 5.10 beta release for the desktop version includes updated print and material profile settings to improve usability.

Versatility with UltiMaker Marketplace: At launch is the availability of the new UltiMaker Nylon CF Slide, a Nylon 612 CF copolymer designed for industrial applications where tribological performance is key. This high-performance, PFAS-free filament delivers wear resistance, temperature stability up to 180°C after annealing, and a Z tensile strength exceeding 40 MPa. The new material serves as a suitable alternative to POM in complex, custom designs. It is designed to reduce friction and increase durability in moving components. Compatibility with the UltiMaker Marketplace allows users to customize material choices based on their needs.

Future-proof production: Built on an updated electronics platform, the S8 features increased processing power compared to its predecessor. This improvement allows the printer to manage the demands of the motion planner and support future updates, enhancing long-term usability.

The UltiMaker S8 increases productivity and enhances part quality while maintaining security, reliability, and ease of use.

For more information, visit ultimaker.com.