Comsol’s Bjorn Sjodin explains the value of reduced order modeling, how chatbots can help simulation beginners and what better AI could lead to.

Engineering.com recently spoke with Bjorn Sjodin, senior vice president of product management at Comsol, about his favorite features of Comsol Multiphysics 6.3, the latest version of the simulation platform.

Today we bring you some bonus questions and answers in which Sjodin muses on the biggest trends in simulation for 2025. Happy new year and happy simulating!

This interview has been edited for clarity and brevity.

Engineering.com: How do you see AI being used in simulation over the next few years?

Bjorn Sjodin: One thing is that simulation engineers, especially beginners at this stage, are using AI chatbots. It’s like having a tutor that you can ask basic simulation questions. ‘If I’m doing this heat transfer simulation, which type of boundary conditions do I have to choose between?’ And the chatbot can give you some answers that will lead you on the way. Sometimes it hallucinates, you know, gives the wrong answer. But if it’s something that is common simulation knowledge by experienced engineers, then the chatbot will probably know some of that. So I think right now it will be very helpful for beginner users.

[One of Sjodin’s favorite features in Comsol Multiphysics 6.3 is a new integration with ChatGPT. -Ed.]

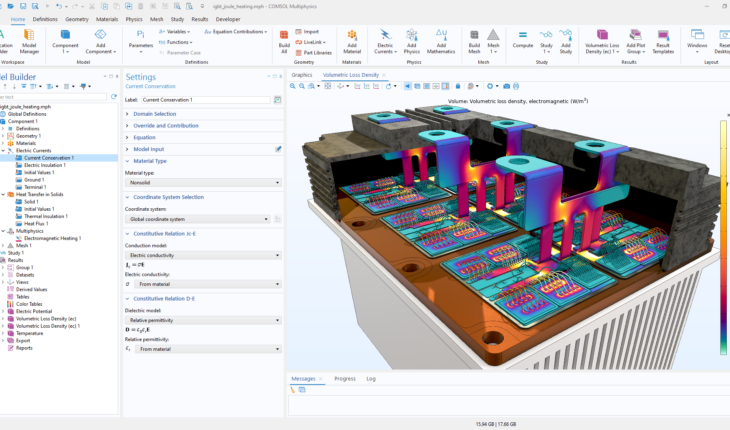

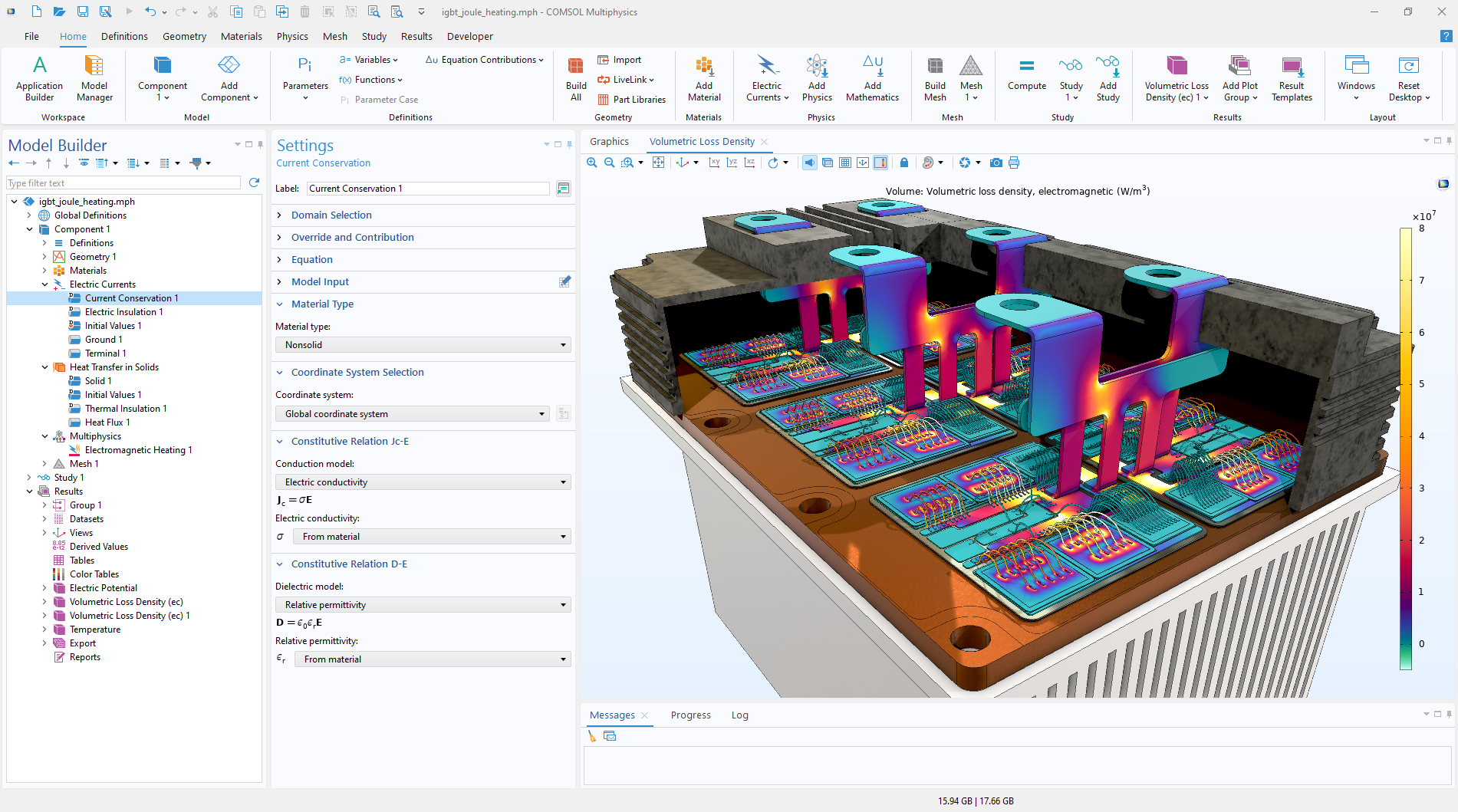

Another area where you can go beyond beginners already is when it comes to API programming. Many of our users would like to automate simulation tasks in various ways, either by writing simulation apps or just to write Java code to automate common tasks that they are doing repeatedly. Our users can use their models to build simulation apps that can be used by those that are not simulation experts, necessarily, but consumers of simulation technology.

And to build those user interfaces, sometimes you would like to write some code. And the chatbots can help you in in programming tasks. They can help you debug your code. They can help you make your code more efficient. And that is something that we are seeing already. So using our new chatbot tool, for example, you can ask it, ‘how can I write a for loop that would automate this task?’ and the chatbot will answer back with code that you can paste into your Comsol model and run. Often it works—not always, sometimes it will give you the wrong answer—but very often it will give you very good answers. If you’re trained in how to guide it, then you can get very efficient and productive with those code snippets.

Do you think it’ll reach a point where it can build the app on its own?

Yes, I think so. That’s where everything is headed. The big question is how fast we will get to that point. No one can answer that, but yes, it is heading in that direction right now.

The biggest limitation that I see is that the current generation of chatbots, they don’t have particularly much spatial perception, so they don’t understand what a CAD model is. They don’t necessarily know the difference between a sphere and a cube and so on. But that will probably change. It can do some of that now, but not to any great extent. When that improves, then you will see more of this complete automation of modeling tasks. I think there’s still a lot of very difficult tasks that the simulation engineers will have to do. It might take decades before we get to full automation there.

In addition to AI, what are the other major simulation trends you’re seeing as we head into 2025?

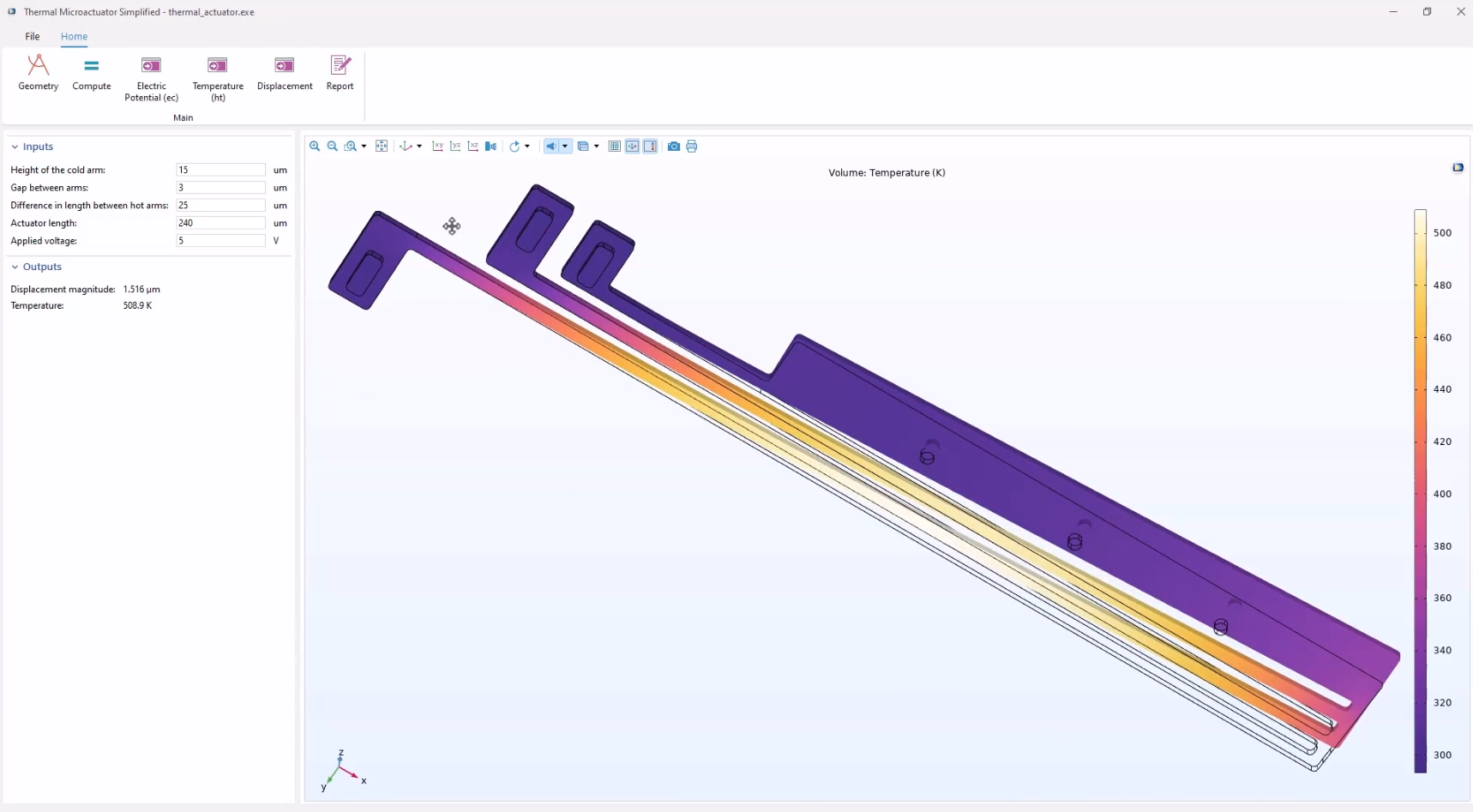

There’s a lot of focus on reduced order modeling and what we call surrogate models, where you basically compactify your heavy simulations to get very lightweight models that can still give you the same results. They are precompiled, we should say. You precompile it for a wide range of parameters so that you don’t have to go to that full simulation that may take hours to run, and instead you get something that only takes seconds to run.

The reason for that trend is that people want to build digital twins. They want to build fast simulation apps. They want to use more complicated models in system simulations. So all of that requires that you can make your models faster to run. And, yeah, neural networks come into play there, but also other technologies, more traditional reduced order modeling technologies.

Could you elaborate on some of those traditional technologies?

Yeah, the most classic technique is that you have maybe a structural mechanics simulation that requires you to solve for maybe a 10 million by 10 million matrix system. There are techniques based on eigenvalue, eigenfrequency analysis that will capture all of the most essential aspects of that model and bring it down from a 10 million by 10 million matrix to maybe a 100 by 100 matrix, and give you almost the same answer as the big model. And if you want to do a system simulation, then that’s all you need. You don’t need the full high fidelity model. You only need maybe some simple inputs and some simple outputs.

So there are traditional techniques for bringing down large system matrices to smaller ones by analyzing the matrix structure in various ways, and those are usually called reduced order models, or model order reduction, or model simplification. They are good for some cases. Neural networks are good for other cases. And there are other machine learning technologies that are useful, and hybrids of these as well.

How flexible are the neural network-based surrogate models? Do slight adjustments greatly impact their accuracy?

They are surprisingly good. You typically have a parametric model, maybe with five, six parameters, and you give it some range. So imagine that you have five, six parameters that are driving your simulation. These could be CAD parameters, material properties, boundary loads, etc. And they vary within max and min values. You feed that through the neural network, and the neural network starts sampling in this large parametric space and building up this neural network model.

As long as you’re staying within those parametric ranges that you pre-trained the model for, it is very good. It could be arbitrarily good. Actually, it could be just as good as the finite element model. The only question there is how much time you are willing to spend on training the model. Do you have five minutes or do you have 50 hours? The more time you have, the more accurate these models can be. So they are basically as good as you have time to train them.

You can give it to someone, and you don’t know which numbers they are typing in, but you know at least that they’re going to be in these intervals. Then they can get an answer in one second instead of one hour.

That’s a huge difference, especially if you have someone on the factory floor or in a production setting. They are not necessarily willing to wait for one hour for the simulation app to come back with an answer. They want an answer in five minutes, max—but probably seconds, and that’s what these surrogate models can provide you.