Autonox and Danobat first to integrate Sinumerik MTR into high-precision robotic solutions.

Siemens has introduced the Sinumerik Machine Tool Robot (MTR), a new industrial robotics technology designed to improve precision and productivity in manufacturing. The Sinumerik MTR is expanding the Sinumerik Run MyRobot /Direct Control solution with new functions and robot types.

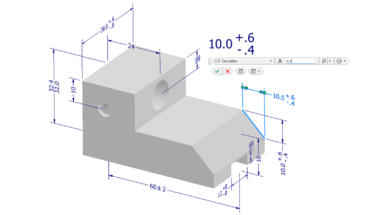

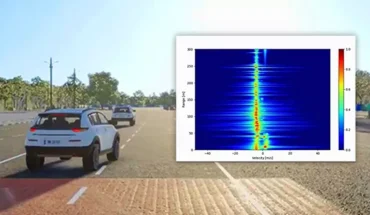

The Sinumerik MTR improves accuracy and productivity across the workspace. It uses an intelligent control system that enables industrial robots to function like machine tools. The Sinumerik MTR enables precise path applications, including machining hard materials like steel, which require higher cutting forces and damping. It improves path accuracy by 200 to 300 percent and increases dynamic rigidity compared to conventional industrial robots. These features make it suitable for aerospace, defense, automotive, and other high-precision robotic applications, such as post-processing 3D-printed metal parts.

In addition to improved accuracy, the new control concept brings a 20 to 40 percent productivity increase. The Sinumerik MTR is well-suited for applications without process forces, such as waterjet and laser cutting. It is controlled by Sinumerik One, Siemens’ digital-native CNC, which includes a digital twin for simulating and testing workflows in a virtual environment. Sinumerik One is also part of Siemens Xcelerator, the company’s open digital business platform.

The first partners to integrate the MTR into their robots are autonox and Danobat.

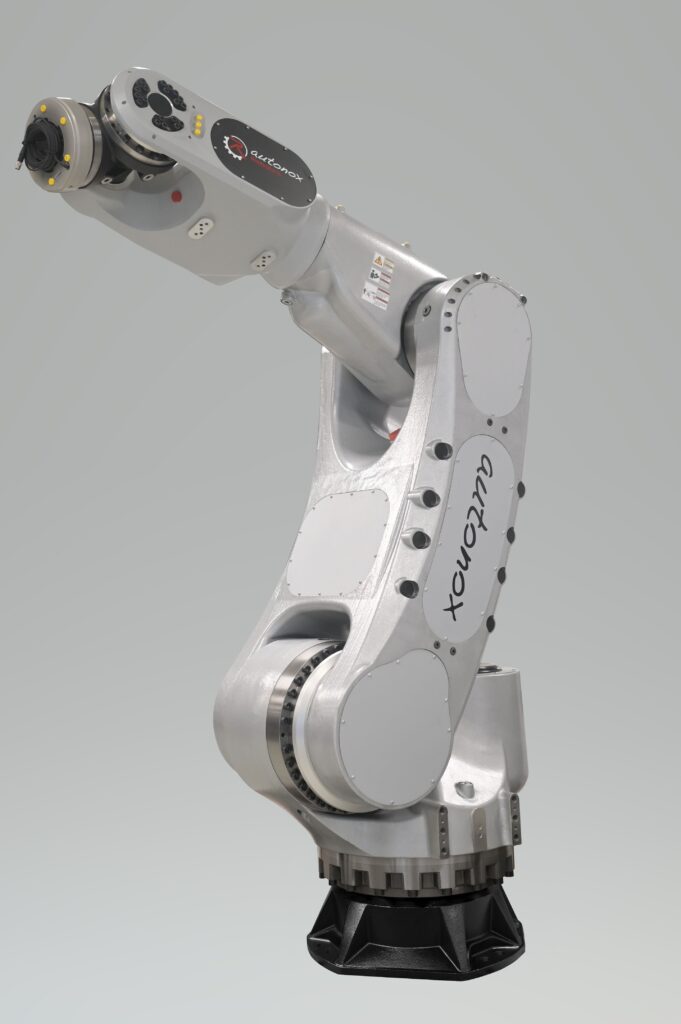

autonox Robotics: A partner for innovative solutions

autonox Robotics is a long-standing partner in the Sinumerik Run MyRobot ecosystem. The company is known for its powerful and reliable robotic solutions that are used in numerous industries worldwide. autonox offers its customers accurate and efficient machining solutions using dedicated CNC robotic mechanisms.

Danobat enters the high-precision CNC robotics market

Danobat is an internationally active consortium and a new Siemens partner. MTR robots are available in models with payload capacities from 220 kg and a 2.6 m reach to 520 kg with a 3.6 m reach. These robots combine the accuracy and stability of a machine tool with the agility and flexibility of a 6-axis robot, which creates new manufacturing opportunities for industries like aerospace, e-mobility, and energy. With Siemens’ partnership and the integration of the Sinumerik MTR, Danobat can expand its high-precision robotic solutions and enter new market segments.

For more information, visit siemens.com.