AI vision software supports robot-operated picking of various objects.

Siemens is showcasing its latest industrial automation and digitalization solutions for intralogistics at this year’s Logimat. In response to challenges such as labor shortages, sustainability requirements, and demographic changes, the company is introducing technologies aimed at improving efficiency and adaptability in warehouse and logistics operations. One of the key highlights is Simatic Robot Pick AI Pro, an industrial vision AI designed to support the development of AI-driven picking robots. Siemens will demonstrate how software-defined and data-driven automation can enhance flexibility in intralogistics. The Siemens Xcelerator ecosystem also plays a role in enabling integration and innovation across platforms, supporting the transition to a more digitalized industrial environment.

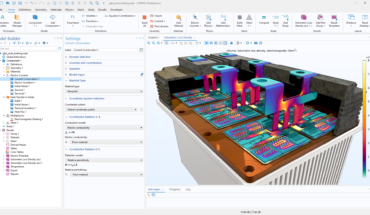

A framework for software-defined automation in robotic small-part picking for intralogistics

Siemens is showcasing Simatic Robot Pick AI Pro, a deep-learning vision software designed for 3D robot picking of various objects without requiring pre-trained models. The software calculates gripping positions in milliseconds, accommodating different shapes, sizes, and packaging types. It supports the development of automated and scalable robot systems for single-piece order picking, particularly in industries like e-commerce, where manual picking tasks are labor-intensive.

Simatic Robot Pick AI Pro is part of Siemens Industrial Operations X, within the Siemens Xcelerator portfolio. This ecosystem integrates software-defined automation and data-driven solutions to enhance system adaptability. Simatic AX, a development environment within Industrial Operations X, enables the creation and management of both physical and virtual controls. Virtual PLCs provide increased flexibility by deploying control systems as software containers using industrial edge management.

The AI vision software enables robots to autonomously identify and handle unknown objects, improving adaptability in dynamic environments. Integration with Siemens’ Totally Integrated Automation (TIA) framework ensures continuous data flow between the robot picking cell and broader operations. Siemens Xcelerator also provides an open ecosystem for collaboration, including partnerships with companies like Zivid for industrial 3D cameras and Piab for vacuum tools, supporting the development of new solutions.

Siemens Industrial Copilot provides support for engineering machines

At the exhibition, Siemens will demonstrate how the Siemens Industrial Copilot assists automation engineers with code generation, fault diagnosis, and the development of complex automation systems. The Siemens Industrial Copilot for TIA Portal Engineering is a generative AI assistant designed for industrial engineering. Integrated into the TIA Portal, it aims to streamline development processes and reduce errors. It also helps less experienced professionals apply their skills more effectively.

For more information, visit siemens.com.