How Squba connectors ensure performance within harsh environments.

TTI has sponsored this post.

An ATV roars through mountainous terrain, its tires kicking up dirt and splashing through shallow streams. Every jolt from the uneven ground sends vibrations through the vehicle. While the thrill of the ride takes center stage, the real challenge often lies in the background — ensuring the ATV’s electrical systems function reliably within such unforgiving conditions. Any failure in these connections could halt the adventure and jeopardize safety.

The challenge to electrical systems isn’t unique to ATVs. From weatherproof security cameras to outdoor lighting, many applications demand connectors that can withstand moisture, dust and vibration. Another hurdle is the need for connectors to be compact as the trend toward miniaturization continues, with shrinking devices leaving less room for electrical components. While space constraints may necessitate smaller connectors, these connectors must still accommodate increasing currents — potentially requiring thicker wires that may not fit in the available space.

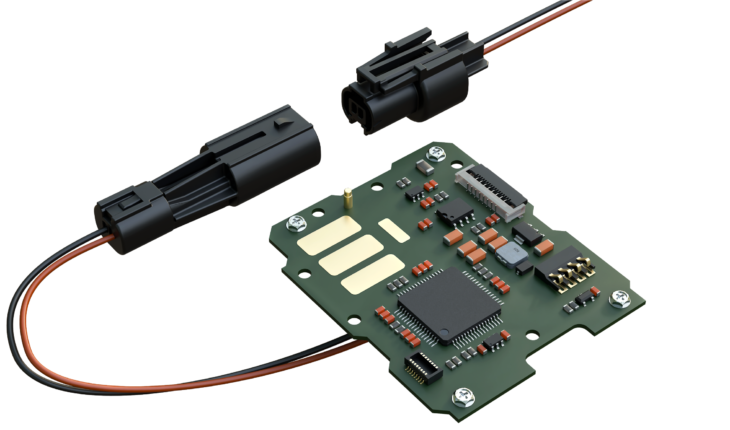

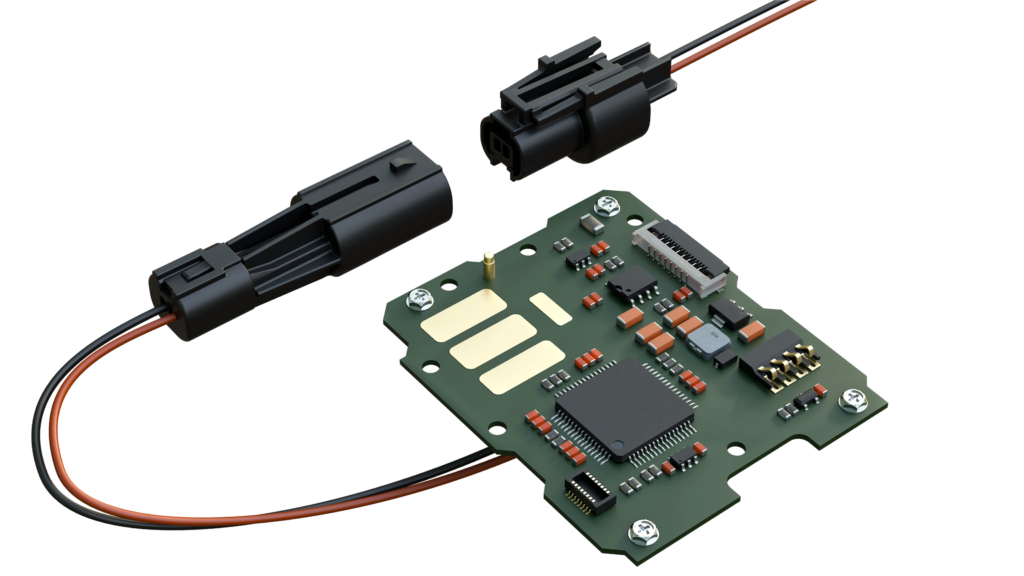

Engineers must navigate these intersecting demands to draw higher levels of power from smaller, more durable connector systems. Enter Squba, a miniature, sealed family of wire-to-wire connectors designed for rugged environments, available from Molex.

Key Features of Squba Connectors

Available in 1.80mm and 3.60mm pitch options, Squba connectors combine space efficiency with the capability to handle currents of up to 14A using 16 to 24 AWG wires. This ensures high power delivery across a wide range of wire sizes. Engineered for harsh conditions, Squba connectors feature UL-approved seals along with the ability to support high operating temperatures.

The connectors achieve an IP68 rating, making them both dust-tight and waterproof. To understand what that means, here’s a breakdown: The first digit of an IP rating ranges from zero to six, indicating the level of protection against small particles like dust, with six being the highest level of obstruction. The second digit ranges from zero to eight and measures resistance to liquid ingress. With an IP68 rating, Squba connectors exceed most industry alternatives, preventing dust ingress entirely and withstanding immersion in water up to 1.5 meters deep for 30 minutes. Therefore, the connectors offer reliable performance in applications where exposure to moisture and debris is inevitable.

Maintaining a secure electrical connection in high-vibration settings is just as essential.

“A customer needs a connector that remains securely in place,” says Jaime Lopez, associate product manager at Molex. “After a product is assembled, the connections must not come loose, as this can lead to fire hazards or cause the electronic device to malfunction.”

A key design feature of the Squba connector system is its protected, low-profile positive latch, which prevents wire from getting caught or tangled. If the latch were too wide, it could allow debris to enter, potentially damaging the terminals and the interior of the connector.

To enhance mechanical durability, Squba connectors incorporate elements such as dual contact points and serrations in the conductor crimp area. The connectors have a tactile feel and produce an audible click upon mating. A primary lock secures terminals with 30N of retention force, and clean-body terminals with wraparound insulation crimps help prevent seal punctures. Interior armor and insert-molded power nails protect pins from damage during manufacturing and assembly.

Sealed caps are a valuable accessory for maintaining connector integrity, especially in rugged or dirty environments. Molex offers sealed caps for Squba connectors to ensure protection during transport or pre-assembly. These caps shield the seals from physical damage, preventing contamination and safeguarding the connectors before they are used. Beyond shielding the seals, Squba’s protective caps guide terminal alignment during assembly, minimizing the risk of punctures or misalignments that could weaken the seal.

When it comes to complex assembly on global manufacturing lines, ensuring the correct mating of connectors is crucial. Squba connectors feature a color and keying system that eliminates guesswork, enabling quick and error-free assembly. Each connector is designed with specific mechanical keys and vibrant colors that correspond exclusively to their matching counterpart. This design prevents cross-mating errors, a common issue in applications requiring multiple, closely spaced connections.

“Often times, a manufacturer in the United States has their product built offshore,” adds John Crimmins, Worldwide Account Manager at Molex. “It could be labeled in English, and the manufacturer may need to add extra labels in different languages. With color and keyed connectors, a person offshore can see blue to blue, green to green, yellow to yellow, without reading anything. Yellow won’t mate with blue, etcetera — so for ease of assembly and manufacturing, it really helps.”

“In our industry, many of these connectors are being mated on the factory floor by people,” says Lopez. “In today’s demanding connector assembly environments, where a worker isn’t always assembling the same thing, color and keyed coding helps! One week, an assembler may be connecting a circuit board for a refrigerator, and the next week, it’s for a dishwasher or something else. Having color and keyed connectors means they don’t have to memorize anything and it’s easier for them to make those connections.”

One benefit that sets Squba apart from other connector systems is that the product comes preassembled. Unlike competitors’ products, which may require seals to be installed separately within the housing and receptacle, Squba connectors arrive ready for use. This eliminates the need for additional manufacturing steps, saving both time and resources.

By January 2025, the Molex Squba 3.6mm and 1.8mm Squba connectors will be available in nine colors.

Applications of Squba Connectors

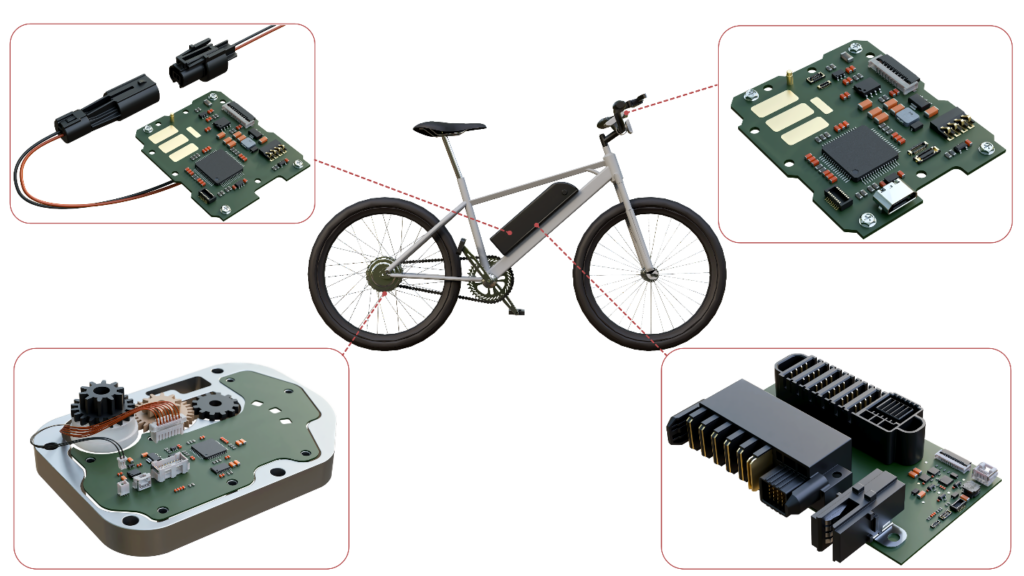

The Squba connector system is well-suited for a wide range of applications where environmental exposure is a concern. In non-traditional transportation, such as e-bikes, ATVs and boats, these connectors handle rugged conditions involving moisture, dust and vibration. In the automotive sector, they are commonly used in areas like door mirrors, where they must endure temperature changes and condensation.

Squba connectors also address the challenges of dust, debris and water infiltration in commercial HVAC systems. These systems often experience condensation due to temperature changes, and Squba’s seals ensure that moisture does not compromise the electrical connections. Additionally, their color and keying features help streamline complicated installations, reducing errors during assembly and maintenance.

Outdoor applications such as solar panels also benefit from Squba’s capabilities. Exposed year-round to rain, snow, and temperature extremes, these systems are dependent on durable, weather-resistant connectors.

“Rugged environments don’t just mean extreme places like mountains or oceans,” says Lopez. “It means anytime the connector has the potential to be exposed to the elements.”

A Connector Built for Every Challenge

Squba connectors tackle the complexities of both compact systems and harsh environments. Their IP68 rating safeguards against dust and water, while robust mechanical features ensure that connections hold firm under vibration. Their color and keying systems eliminate mating errors and simplify assembly. From e-bikes to HVAC systems, Squba connectors demonstrate resilience in a variety of use cases, offering engineers a dependable solution against challenging conditions.

To learn more, visit Molex at TTI.