What began as a Nitinol processing service more than 30 years ago has transformed into a fully integrated Nitinol production program – from raw material melt to customized finish – with Fort Wayne Metals emerging as the largest independent producer of Nitinol products in the medical device industry.

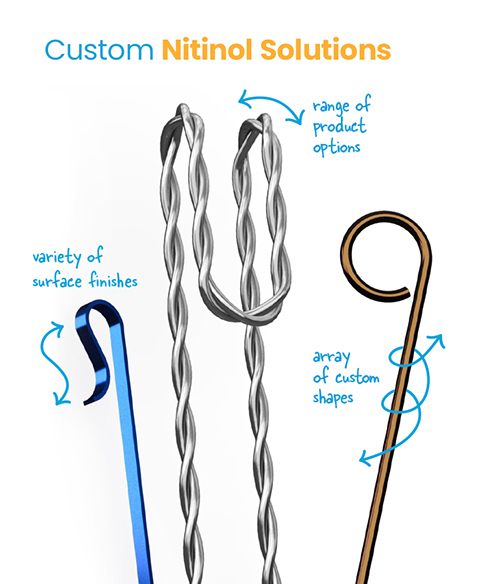

Fueled by an innovative spirit and a commitment to support customers from concept to full-scale production, we continuously expand our manufacturing capabilities and deepen our materials expertise. Ultimately, this leads our team to create tailored Nitinol product offerings – bar, sheet, custom-shaped wire, actuator wire, and shape-set parts – used in medical devices ranging from stents and guidewires to retrieval baskets and orthodontic files.

Our melted Nitinol can be used in our broad range of product offerings because we offer both standard material conforming to ASTM F2063 and a premium option for fatigue-dependent applications. Additionally, to meet the growing demand for increasingly smaller and more complex medical devices and less invasive treatments, we are a global leader in precision fine and ultrafine wire capabilities – customizing material in diameters as small as 0.0127 mm [0.0005 in]. Since 2012, Fort Wayne Metals has sold more than 650,000 pounds of our melted Nitinol in product form primarily to the medical device market.

Check out our entire Nitinol portfolio at fwmetals.com/what-we-do/materials/nitinol

Expanding Nitinol melting capabilities

With an eye always toward the future, CEO and Chairman Scott Glaze has long believed Fort Wayne Metals could better support customers by building a state-of-the-art facility dedicated to melting Nitinol, positioning the company to control the entire production process of the material.

“By controlling the process from start to finish, we can provide consistent quality and delivery,” says Glaze. “This is especially important in the medical device industry, where delays can have significant consequences.”

The amount of Fort Wayne Metals-melted Nitinol supporting the medical device industry only continues to grow. We doubled our Nitinol melt output in 2023, with 74% of all the Nitinol products sold made from our melted material. As a result of Plasma Arc Melt furnace upgrades this year, we substantially enhanced our melting capabilities and capacity. What’s more, a second VAR (Vacuum Arc Remelting) furnace becoming operational in early 2025 will again help double Nitinol capacity, enabling us to melt as much as 1,000,000 pounds of Nitinol annually.

Because of these recent expansions and our vertical integration to secure the Nitinol supply chain, we are in a position to provide more advantageous lead times, minimize potential bottlenecks, ensure quality control, offer stable pricing, and give customers peace of mind as they scale their operations or develop new products.

“Our strategic investments reflect our long-term commitment to the medical device industry,” Glaze explains. “We are all in, and we want our customers to have confidence in us as their partner of choice, now and in the future.”

Get in touch with a technical representative in your area: fwmetals.com/contact/find-your-rep

Broadening Nitinol product offerings

Expanding our melting capabilities is not just about volume – it’s also about sustaining the flexibility to do what we do best – innovate. Whether creating a new product form or developing cleaner Nitinol used to advance cutting-edge medical devices, we help customers push boundaries.

We’re driving progress with the launch of three new Nitinol products in 2024:

- Nitinol DFT® flat wire: Significantly increases radiopacity compared to round wire, enhancing the visibility of medical devices in X-ray imaging

- Nitinol helical turkshead wire: Offers the same superelastic properties with reduced friction, popular for guidewire applications

- Nitinol <28µm: Low-inclusion material customized for applications where fatigue is critical

These recent innovations reflect our diverse and growing product portfolio and are the result of our exceptional research and development capabilities that leverage our technical expertise and advanced processing technologies to support prototyping and next-generation projects. “We see ourselves as more than a supplier – we’re an innovation partner,” Glaze explains. “Our goal is to help our customers achieve their vision, whether it’s a breakthrough device or a lifesaving technology.”

Fort Wayne Metals has been at the forefront of this transformative material’s journey since 1991, serving as a reliable and trusted collaborator to medical device manufacturers worldwide. “By combining technical guidance, strategic investment in technology, and a relentless focus on product innovation,” says Glaze, “we are not just meeting the needs of today’s medical device market – we are shaping the future of what’s possible with Nitinol.”

Learn more about our history of innovation through R&D at fwmetals.com/resources/technical-literature

About Fort Wayne Metals

A leading manufacturer of precision materials used in life-improving medical devices, Fort Wayne Metals is dedicated to making Northeast Indiana and the world a better place. As committed as we are to supporting our customers’ medical technologies, our more than 1,700 employees are just as committed to contributing to community organizations and causes. Whether it’s providing the world with customized material solutions to support the medical device industry or championing efforts that lift up local communities, we are passionate about making lives better.

Ready to talk? Let’s connect you with a technical representative in your area fwmetals.com/contact/find-your-rep

Sponsored content by Ft. Wayne Metals