From Solidworks 95 to ColdSnap’s futuristic ice cream machine, here’s everything you missed at Dassault Systèmes’ annual user conference.

Users of Solidworks, the 3DExperience platform and other Dassault Systèmes products flooded into Houston, Texas this week to explore the latest in design and simulation software at 3DExperience World 2025.

This was my third 3DExperience World, and one of the highlights of the annual event is always the 3DExperience Playground, where exhibitors showcase their technologies, software and applications of 3DExperience tools. This year was no exception, with booths featuring the latest workstations, 3D printers, CNC machines, apps and more.

While the event showcased a huge variety of technologies, many standout exhibits fell into four categories: maker projects, competitions, robots and applications of the 3DExperience platform.

Robots were everywhere

It was hard to escape the robots at 3DExperience World this year. There was an emphasis on software to program robots and make it simpler to bring them onto the manufacturing floor. BlueBay automation, Spartan Robotics and Tormach all had robotic demos running constantly on the floor.

Tormach showcased their latest CNC mill, the 1500MX, and how they designed it to integrate with one of their ZA6 robotic arms. Through a side door that opened after operations were complete, the arms unloaded the completed part, set it in the table, and selected a new unfinished part to insert into the mill so that operations could begin once again. This was an automation solution the team worked on last year after customer requests to move their CNCs into a higher production application, and they started selling the solution this year.

Speed modeling competitions

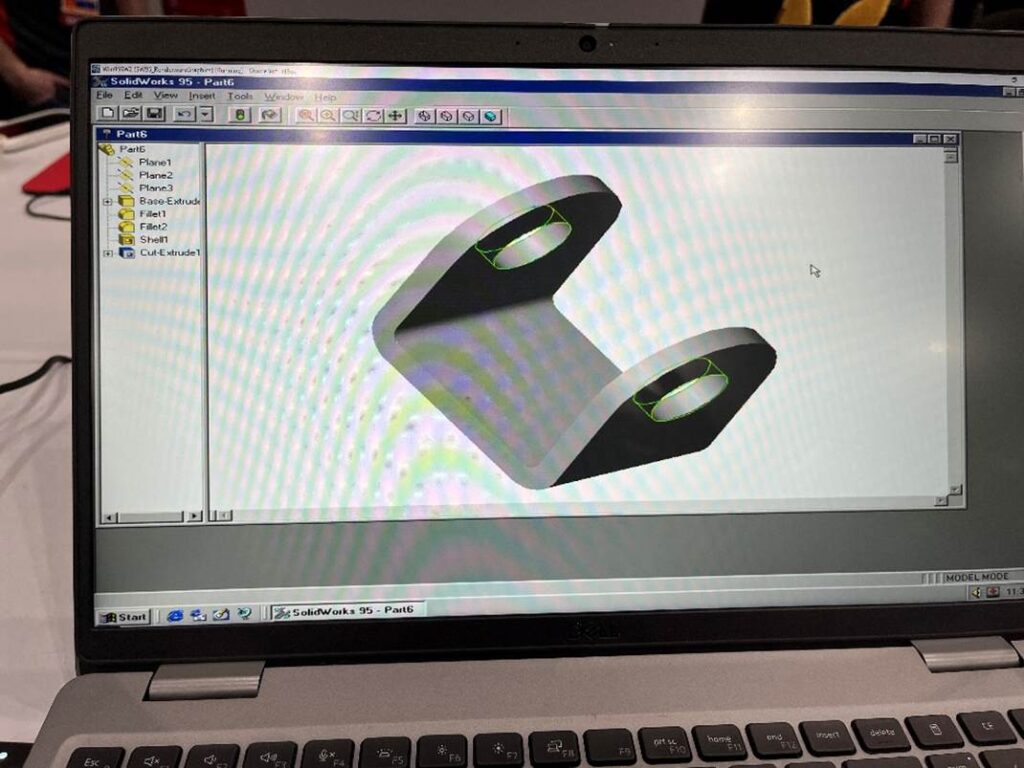

Solidworks is officially celebrating its 30th anniversary this year, and the software sure has come a long way in that time. How do I know that? Well, I got test out my skills modeling in Solidworks 95 on a laptop running a Windows 95 emulator.

Attendees could take on the challenge of designing a specific simple part in 10 minutes or less in Solidworks 95 and win some swag if they succeeded. Even though there were step-by-step instructions, a number of people weren’t able to make it under the wire!

I was successful, but I will say it was stressful. As a reward I received a cord organizer, Solidworks stress cube, some Solidworks socks, a Solidworks 95 collectible CD-ROM that I am going to have to take to my local library to check out, and in classic 90s fashion, a Solidworks Tamagotchi. Afterwards I tried my hand using the software in a mock 90s office setup that was running Solidworks on an actual 90s computer.

Right across the aisle a head-to-head Solidworks modeling battle was also happening during Model Mania Xtreme. Complete with commentators and a boxing bell that went off to mark the start of a new round, it was hard to miss. The bell was a present sound in the Playground throughout the entire event.

Maker projects

The Solidworks for Makers program was highlighted in the general session and given primate real estate in the Playground.

The maker exhibit had a large interactive component with a collaborative maker project that attendees could participate in front and center. Attendees could make feathers through different methods like leatherwork and resin pouring, and customize the feathers with paint, glitter, stamping and more. After creating their feather, attendees added it to a large freestanding wing structure which became ever more colorful over the event.

Also in the maker booth were some interesting projects using 3DExperience platform tools, including the OpenR2 project, which has appeared at 3DExperience World a number of times.

OpenR2 is an open-source effort to research and document the specifications of the original R2D2 robot prop built in 1976 for the original Star Wars movie. The team is meticulously documenting the models of all the parts used in the 3DExperience platform, as well as acquiring the original parts used to create a perfect replica, making a virtual museum piece. They have officially tracked down the last original part they needed and are moving into the wiring phase this year.

Other projects featured in the maker booth included Gigabot 3D printer and its maker applications, as well as fashion projects created in Solidworks and xDesign by Rachael Naoum.

Unique customer use cases

Who had the most consistent crowd around their booth? Well, if you’re handing out free food or drinks you can expect to have a line on the floor at 3DExperience World (think robot baristas from past years). This year ColdSnap was the crowd favorite.

ColdSnap has created a Keurig-style ice cream machine that makes a bowl full of ice cream from a shelf-stable can of ingredients in two minutes. The team behind the machine used 3DExperience tools for design, FEA and CFD simulations.

President Matthew Fonte, who was on the floor talking to attendees and handing out samples, said ColdSnap has completed their design stage and is fully in the production and sale of their product. While they are offering them to home buyers, ColdSnap envisions the machines in country clubs, senior living centers and more.

They offer many flavors. I got to try chocolate and vanilla, which were solid.

Around the corner was another booth that was attracting crowds: Grind Basketball. Grind has created a fully pneumatic device that captures hoop shots, both missed and made, and returns the ball back to the shooter. The company used Solidworks for the design process, especially the sheet metal tools and sheet metal converter.

“I always wanted to design something that if you could easily repair with your hands, you could keep running for 100 years,” said Elliott Martinez, industrial designer at Grind. Martinez prioritized that aspect in the design, making all fasteners and parts easily accessible.

The Mobility Independence Foundation also had an impressive setup showcasing their initiative to create and distribute open-source accessible technology. On prime display was a wheelchair that they are reverse engineering from a previous company that went out of business. They are using this existing motor design to create essential models, as well as designing some from scratch and uploading them with the 3DExperience platform. The goal is to both produce the wheelchair as well as make all the files accessible to anyone who would like to create one themselves.

Honorable mentions

If a company’s software or hardware is being used to produce any part of racecar—especially F1—they probably featured that car in their booth. Cadence showcased their CFD work with the McLaren F1 team on optimizing their front wing design. HP, the title sponsor of the Scuderia F1 HP Racing team, had some model cars from past years.

I hope you liked Houston because 3DExperience World 2026 will be headed back to Houston, Texas from February 1 – 4, 2026. See you all here again next year!