Breaking down strategies for optimizing additive manufacturing with simulation.

The effective use of engineering simulation can make the difference between a successful 3D print and a failed one. Less drastically, simulation can also help optimize additive manufacturing (AM) build times and material usage in a variety of ways. While there are literally dozens of methods that involve using simulation to optimize 3D printed parts and 3D printing processes, these generally fall under one of four distinct strategies.

How to optimize AM material management with simulation

In contrast to subtractive manufacturing processes, AM can drastically reduce material waste since the majority of what’s deposited, polymerized, sintered, etc. ends up in the finished product. Compare this to the old adage in machining: “If you’re not making chips, you’re not making money.” Of course, the specifics of how 3D printing helps manage material usage depend on the particularities of the process and (more significantly) the post-processing involved.

Nevertheless, there are several ways simulation can help optimize material management. For example, simulation can help with designing the complex, conformal lattice structures that reduce material usage without reducing part strength. Simulation can also aid in predicting where porosity is most likely to occur so that (depending on the material) engineers can allow for it in regions where strength is less critical. Of course, the actual material savings in such cases will be minimal.

More significantly, simulation can inform adjustments to infill density and density gradients, once again reducing material use without compromising structural integrity. In the most advanced cases involving multi-material prints, simulation can help AM engineers assign materials based on structural needs to minimize the use of more expensive materials.

How simulation helps optimize geometry and part design in 3D printing

It’s often said that “complexity comes for free” with 3D printing, in the sense that creating additive parts with highly complex geometries adds far less build time than trying to create an equally complex part with conventional manufacturing. While there is some truth to this platitude, the physics of AM processes still place additional burdens on designers, particularly when it comes to complex components.

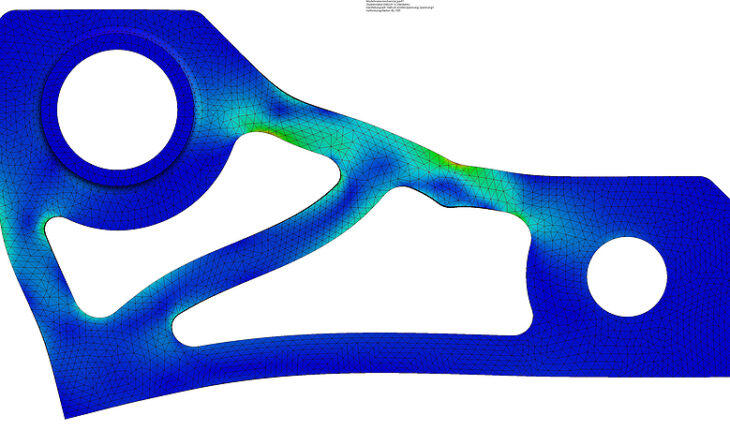

Fortunately, simulation can help take advantage of this feature of 3D printing. Topology optimization is a prime example, with simulation tools helping engineers to adjust part geometry so that they can remove unnecessary material from low-stress areas, resulting in faster builds and less material usage. Simulation can also help identify the optimal orientation for a part, minimizing the need for sacrificial supports and making it easier to remove parts from the build plate once finished.

It’s also worth bearing in mind that just because something is free doesn’t mean it’s desirable. Using simulation to identify features that can be simplified or even eliminated without compromising performance can reduce complexity and thereby save both time and materials.

How to enhance thermal and structural control in AM with simulation

Controlling shrinkage, distortions and residual stress is key to success in additive manufacturing, especially when 3D printing metal. In processes such as laser powder bed fusion (L-PBF), there are myriad parameters operating at the micro-, meso- and part scales that can influence the quality of 3D printed part.

Finding the right balance between the forces operating at all three levels is extremely challenging, especially during the printing process itself. This is why conducting careful and comprehensive simulations prior to 3D printing a new part is so important.

In both polymer and metal AM processes, simulations can help predict and adjust for material shrinkage, reducing the risk of parts being out of tolerance and either needing to be further machined or reprinted altogether, both of which increase overall cycle time. By the same token, simulating the thermal distortion of 3D printed parts enables engineers to make the appropriate adjustments – either to the design or the process – and ensure the parts come out right the first time. Residual stress is a well-known challenge for many additive processes, but simulation can help engineers anticipate where it will occur and compensate for it, again via either design or process adjustments.

How simulation improves process efficiency and path planning in 3D printing

For all the differences between subtractive and additive manufacturing processes, there are nevertheless similarities in how they benefit from simulation. For example, simulation can help engineers identify optimal toolpath strategies, whether for cutting tools or print heads. In the latter case, simulating zig-zag versus concentric toolpathing, for example, can help identify when it’s acceptable to use the faster option (zig-zag) or when the slower option (concentric) is worthwhile for greater strength or better surface finish.

Another example that’s more specific to AM involves printing multiple parts in a single setup. In such cases, simulation can identify which, if any, parts need specific parameter adjustments to ensure a successful print. Similar principles apply for simulating parts with variously detailed regions or complex features, where print speeds and deposition rates may need to be reduced.

Finally, simulation can improve 3D printing process efficiency by optimizing energy consumption, particularly in high-energy additive processes such as L-PBF or direct energy deposition (DED). Simulating the energy requirements for different printing strategies can give engineers key insights into the most energy-efficient paths and machine settings, reducing the risks of overheating or material degradation.