BM-Stamp helps automotive manufacturers lower costs and enhance precision.

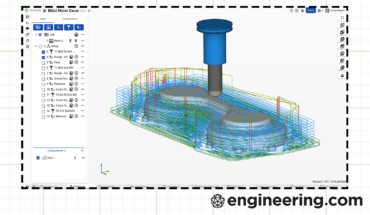

ESI Group has announced the launch of BM-Stamp, a stamping simulation tool that allows engineers, including those with limited experience in finite element analysis (FEM) or meshing, to run simulations ranging from early feasibility checks to detailed stamping analysis. BM-Stamp helps automotive manufacturers lower costs and enhance accuracy by providing faster, more reliable simulations to meet industry demands for reduced production time and expenses.

BM-Stamp offers an intuitive, process-focused experience that reduces the initial learning curve dramatically, enabling engineers to achieve expected efficiency quickly. Not only does BM-Stamp match the productivity of current tools, but it also enhances accuracy which results in reduced material costs and fewer physical try-outs.

A building block to ESI’s complete and seamless virtual manufacturing chain

BM-Stamp integrates with ESI’s broader virtual manufacturing workflow, supporting processes from single-part manufacturing to assembly and structural analysis. This integration helps manufacturers track the origin of defects, identify influencing stages of the process chain and avoid over-engineering by focusing on key parameters and steps. Overall benefits are a reduction of errors and an accelerated time to market.

For more information, visit esi-group.com.