The latest update adds support for 64 KUKA cobots in ENCY Robot, including 7-axis and 6-axis SCARA models.

ENCY Software has released update 1.0.6 for entire ENCY product line. The ENCY 1.0.6 update improves interface functionality, optimizes task management, and adds new features for robotics programming and cloud collaboration.

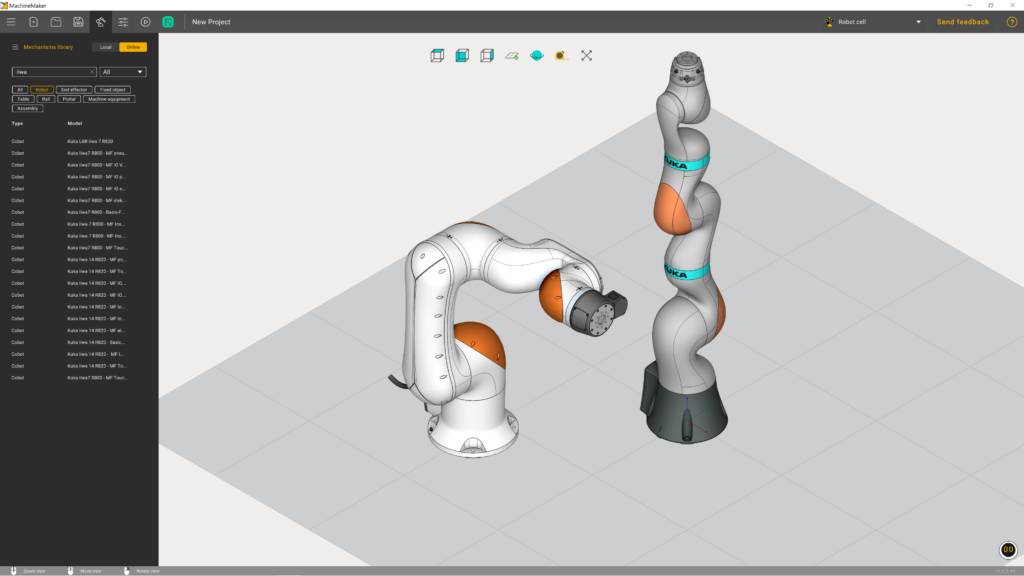

Support for 7-axis robots in ENCY Robot

The latest update introduces support for 64 KUKA сobots in ENCY Robot, including 7-axis and 6-axis SCARA robots, such as KUKA iiwa and KUKA LBR. This expansion extends the software’s functionality in robotic programming, enabling support for a wider range of automation tasks.

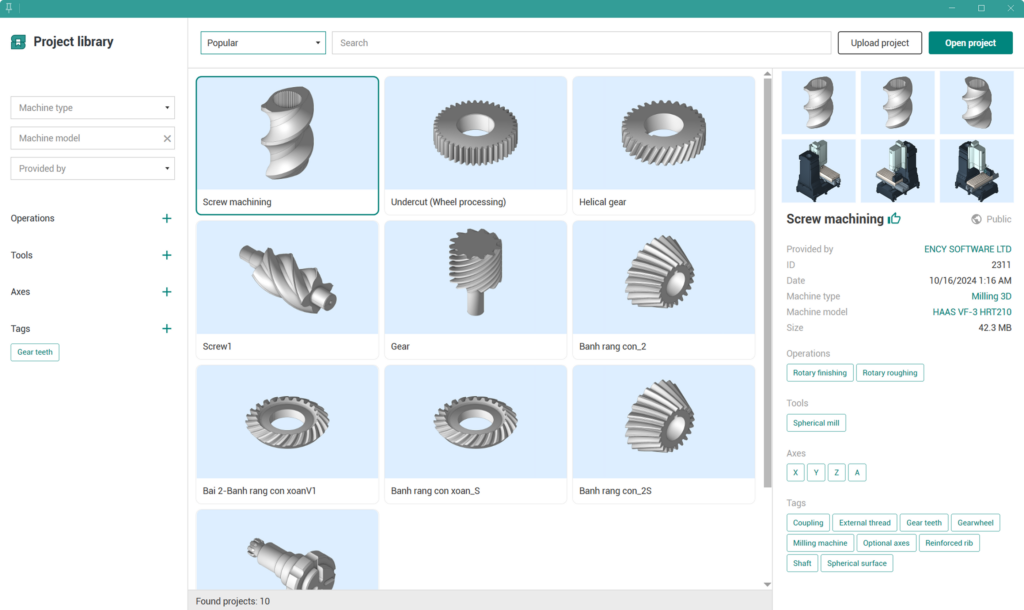

Enhancements in the online project library

- Tagging for public projects: A new AI-powered tagging system has been introduced to improve searchability within the online Project Library. With over 400 projects available, users can now filter results effectively. For example, applying the statue tag will display machining projects related to statues.

- Automated AI tagging: AI assigns relevant tags to both existing and newly uploaded projects, improving categorization and searchability.

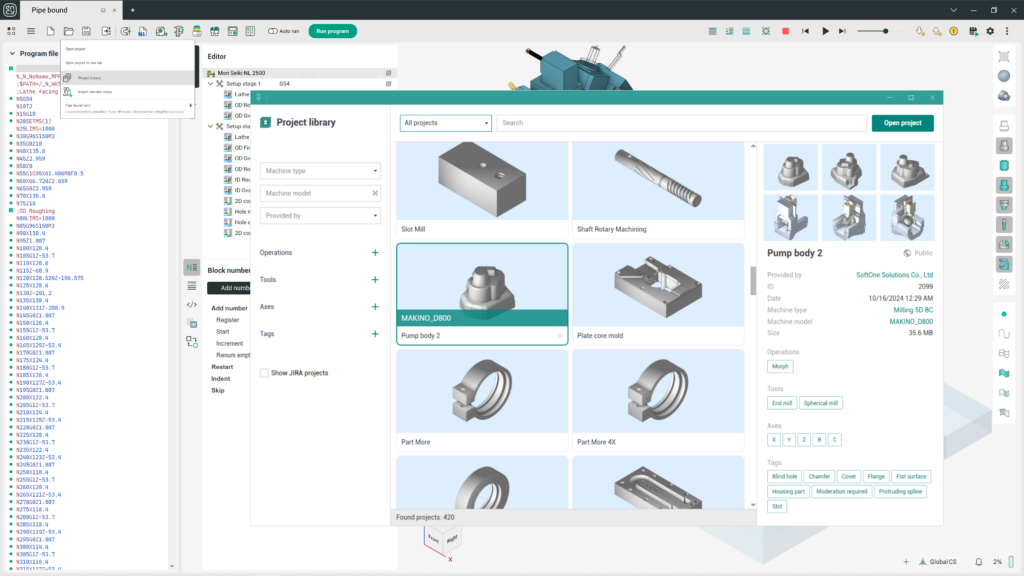

Project library now available in ENCY Tuner

- The Project Library feature, previously available only in other ENCY products, has been added to ENCY Tuner.

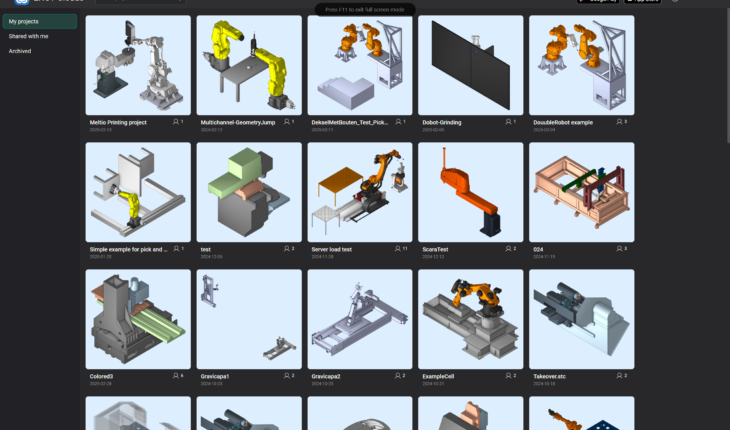

New features in ENCY Clouds

- Integrated Screen Recording: ENCY Clouds enables users to record their screens directly from ENCY or ENCY Robot without additional software. Recordings are stored efficiently with audio support and can be accessed through the interface.

- Browser-Based Project Opening: Projects can be opened directly in ENCY, ENCY Robot, or ENCY Tuner from a browser, improving workflow efficiency.

Usability improvements in ENCY 1.0.6: Enhanced precision and interface updates

- In the 6D contour operation, the 5D curve task displays the arbitrary vector angle with a precision of up to two decimal places.

- Updated Smarthints for approach/retract parameters, thread-cutting operations, and part transfer processes, providing clearer guidance.

- Redesigned the Tool Reach inspector interface and expanded its functionality for better tool management.

- The “Delete chips” parameter is now enabled by default for part-off with takeover operation.

- Users can now interactively move tools on any tab of the Operation Properties inspector within the machining window, improving workflow flexibility.

- Updated operation export data and introduced a revised operation export file format to enhance compatibility and data accuracy.

Bug fixes in ENCY 1.0.6

The update resolves stability and functionality issues, including errors related to project saving, licensing activation, and report generation. It also improves visualization, tool orientation data, multi-channel robotic machining, and NC Tuner interface elements. Additionally, corrections were made in machining operations, the postprocessor generator, and CAD module functions to enhance software performance.

Note: The 1.0.6 update is available to all users with an active annual support contract (SMC).

For more details, visit encycam.com.