By Parker Aerospace

What were you thinking about the last time you traveled on a plane? Your seat assignments, the weight of your suitcase or finding the right gate? Perhaps you were worried about takeoff or experiencing turbulence on your flight. But did you ever stop to wonder about the braking system, about if—or how—the plane would land and stop safely?

For the millions of passengers flying in and out of airports every day, it’s easy to take touchdown for granted. But for the team members in Parker’s Aerospace Group, braking has the potential to revolutionize air travel and pave the way for a better tomorrow.

“The hardest part is not making the airplane fly,” explains Grant Puckett, group chief engineer for electrification at Parker Aerospace. “We’re focused on making sure you land safely and continuing to provide the assurance society expects from the airplane industry.”

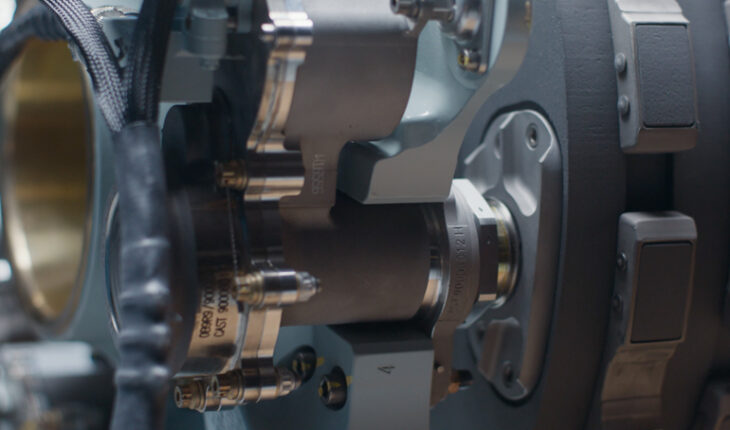

Now imagine boarding a plane where the brakes are as efficient and reliable as those in your electric car. While consumers may still be relatively early in their adoption of electrification technology, the aerospace industry has been working towards electric planes for decades, seeking ways to increase efficiency and reduce environmental impact. And Parker’s new electric braking system (Ebrake®) not only enhances safety and efficiency but also reflects progress toward greener, more sustainable air travel.

“Airplanes need to be able to stop when they land in all imaginable conditions,” says Puckett. “Our Ebrake uses electronic power to do that. This development is crucial because it provides electronic control for anti-skid algorithms and unique diagnostic capabilities, all while using less power and contributing to overall fuel savings.”

Traditional hydraulic braking systems are powerful but complex, and often require extensive maintenance. In contrast, the Ebrake’s electro-mechanical actuation is simpler, more reliable and more efficient.

“By eliminating hydraulic systems we reduce the plane’s weight, leading to significant fuel savings and easier maintenance,” Puckett adds. “This not only benefits airlines but also helps the environment by reducing carbon emissions.”

Indeed, Parker’s acquisition of Meggitt in 2022 has created a synergy of complementary technologies, particularly in electrification.

“The blend of Parker and Meggitt offers us the opportunity to think about vertical integration and draw on each other’s strengths to deliver superior solutions to our customers,” summarizes Jennifer Osbaldestin, general manager of Parker Aerospace’s Braking Systems Division.

The system’s successful implementation on the Airbus A220 is proof positive: “The Ebrake system is not only reducing maintenance needs but also enhancing safety by eliminating the need for hydraulic oils,” says Osbaldestin. “This innovation aligns with the growing demand for more sustainable and efficient aviation solutions.”

It also aligns with Parker’s Purpose, Enabling Engineering Breakthroughs that Lead to a Better Tomorrow. “Our Ebrake system is not just about efficiency; it’s about making a real impact on our environment,” emphasizes Puckett. “By reducing fuel consumption and emissions, we’re helping to create a more sustainable future for aviation.”

Looking ahead, there are several opportunities on the horizon, with advancements in air mobility and sustainable technologies leading the way. Osbaldestin shares her optimism: “The advanced air mobility sector is booming, and Parker is at the forefront with our innovative Ebrake technology. We’re committed to providing smarter, easier-to-maintain solutions that support our sustainability goals.” By combining the strengths of Parker and Meggitt and focusing on innovative solutions, Parker is not only improving the efficiency and safety of air travel but also setting a standard for future technological advancements. This purpose-driven approach ensures that every engineering breakthrough contributes to a better, more sustainable world.