Exploring the shipbuilding process with modular design and sustainable technology.

I’ve been on my share of cruise ships, large and small, over the years. Especially when on the larger oceangoing vessels, I’ve marveled at their complexity — how they function like small movable cities, providing guests everything from guest quarters to food and drink to entertainment. So, for the mechanical engineer in me, it was a treat to be offered an exclusive inside look at how these colossal ships are constructed.

Celebrity Cruises is currently building the Celebrity Xcel, through shipbuilder Chantiers de l’Atlantique in Saint-Nazaire, France. The facility is the largest assembly dock in Europe, with 3,800 employees and another 6,200 contractors on site at any given time.

The Xcel is the fifth vessel in what Celebrity calls the Edge Class, its latest iteration of luxury ships. I toured the shipyard and chatted with executives including Captain Manolis Alevropoulos, VP of marine operations, Stavros Zannikos, chief engineer; Eric Perennou, senior project manager of Edge Class; Henri Doyer, SVP of projects and engineering; and Ivan Klaric, project manager for the Xcel.

Shipbuilding is a complicated process for sure. Even within the Classes, the individual ships do vary somewhat, as the company receives feedback on everything from the crew to the engineering team to the passengers once the ships are put into service. That influences future ships in the Class.

It was fascinating to learn from them how the most improvements on a ship generally happen between the second and third ship of a Class. While all the ships are quite similar, adjustments to both behind-the-scenes areas and public spaces do evolve. By the time the first ship goes into service, the design (or even construction) of the second one is already in progress. So, it’s the third ship that really receives the most tweaks in the design and construction phases.

“The most important changes we see are between ships two and three,” said Doyer. “Really, we start to master and have very good knowledge of the inside of the project already on ship number two. You have the low-hanging fruit that you catch on the second one — but the numerous little, tiny things that, as a whole, can make us better are with ship three. Mainly, this is building efficiency, meaning shortening construction times and also cutting our costs. The more upfront we build and assemble, the less difficult the logistics are. The more modular we are, the more efficient we are in building.”

And modularity is a key, as I discovered. In Saint-Nazaire, up to six ships can be built at a time, although they’re all in different stages. For the Xcel, the design process is a long and staggered journey:

- Basic design: October 2022 to April 2023

- Detailed design: April 2023 to October 2023

- Industrialization: August 2023 to April 2024

- Panels and blocks construction: October 2023 to April 2024

- Ship assembly and outfitting: May 2024 to January 2025

- Cabins prefab and loading: June 2024 to April 2025

- Outfitting and commissioning: February 2025 to October 2025

The actual construction work starts on dry land, as the first steel is cut, and these large pieces of the hull are welded together into what are called blocks. Eventually, different blocks are loaded into the drydock, a large berth that can be flooded with water later in the construction process. Putting the ship together is like working with enormous Lego pieces. There are more than 40 blocks that comprise the ship; these are built individually on land and eventually moved into place with enormous cranes. Then, they’re connected and welded together, and work inside continues until the next piece is finished.

One of the most interesting things about the shipbuilding process that I discovered was this: On one hand, it’s very much the opposite of a manufacturing assembly line. You’re building one ship that’s unique in many ways, even if it has past siblings from the same Class. Restaurants and public areas and even overall sizes can vary from ship to ship. On the other hand, the construction of the crew and passenger cabins is very much a traditional assembly line process. You need hundreds of specific types and sizes of cabins, so the work here is very repetitive and predictable. Cabins are built as 80% finished products that are eventually hoisted onto the ship’s superstructure and “plugged in” once installed. Once installed, the cabins only take about 40 hours to complete.

I visited days before the critical “float out” of the Xcel — the point where the drydock is flooded with water to float the ship for the first time. At this point, all crew cabins had been installed, as well as 20% of the passenger cabins. Once floating, the ship is pushed by tugboats out into the Loire River and through another channel to a different area of the shipyard, where the rest of construction happens. This frees up the drydock for the assembly of the next ship.

Going virtual

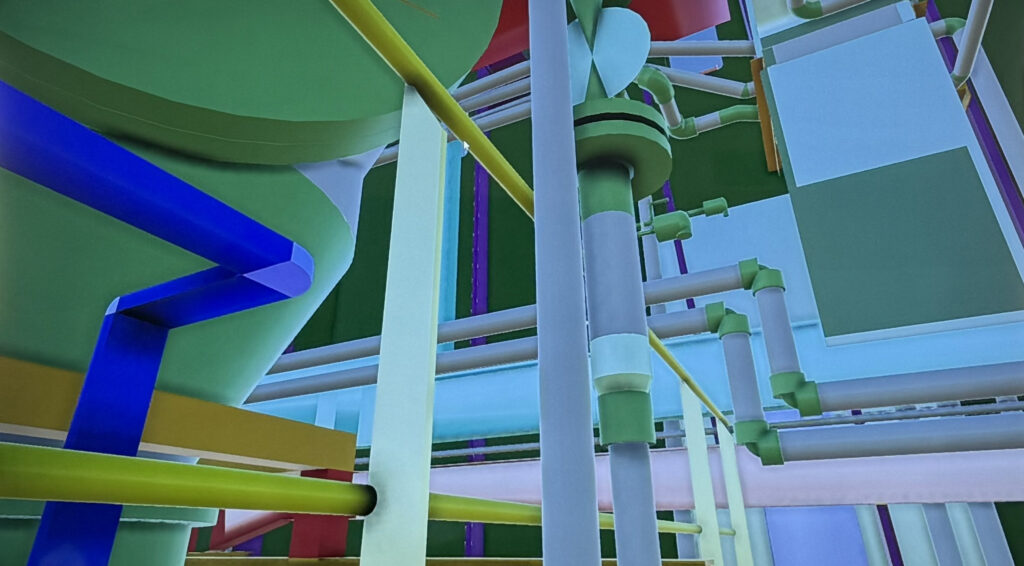

I was allowed into Chantiers de l’Atlantique’s virtual engine room area, where early in the design process, engineers can move around in a 3D simulation of the engine room to coordinate piping, cabling, equipment, and componentry. Here, Smart Mind is used as the CAD program. But the team then uses Unity (a cross-platform game engine, usually used in gaming applications) to take the Smart drawings/renderings and view them through the virtual reality goggles.

I tried out the system, and it was intuitive to use and quite simple to move around and get your bearings. With some of these systems, it’s easy to experience disorientation or motion sickness, but I had no problems getting acclimated quickly, and it was comfortable to use.

The team explained that the Celebrity Edge, the debut ship in the Edge Class, was one of the first ships to be designed by 3D software.

For the cabin design, which also happens on site, Solid Edge is used, Perennou said.

“Solid Edge is useful when you have plenty of parts to specify, as per the cabins,” he said. “It was chosen for this reason and because it was easy to interface. Also, for the production, it was helpful. There are many areas where we don’t build [the subsystems] ourselves, so here we don’t need detailed bills of materials. And Solid Edge allows us to have easier access to the volumes of a space, as well as the settings, the lighting, and so on.”

Green on board

We were able to go on board the Xcel and take a tour, which was a bit mind-blowing. Seeing the intricate infrastructure, the miles of cabling and wires, not to mention the complex HVAC and engine control systems, was impressive. Workers everywhere were busy, especially along what’s called “I-95,” a sort of super-highway access corridor that runs nearly the length of the ship. We saw the engine room, public areas, one of the installed passenger suites, and even the bridge.

Celebrity’s parent company, Royal Caribbean Group, has a sustainability program called Destination Net Zero, which it describes as a comprehensive decarbonization strategy that includes pledging to achieve net zero emissions by the year 2050. This includes the delivery of a net zero cruise ship by 2035.

Xcel takes a step in that direction, with Royal Caribbean Group’s first tri-fuel capable engine system, which includes the ability for the ship to run on methane. Two of the ship’s engines, produced by Finnish manufacturer Wärtsilä, are converted Wärtsilä 46F engines; they can also run on two conventional fuel types. When running on methanol, the ship’s emissions of sulfur oxides, nitrogen oxides, and particulate matter are significantly reduced, according to Wärtsilä.

“Wärtsilä has invested heavily into researching viable future carbon-neutral fuels for the marine industry, and methanol has emerged as one of the most promising candidates. This will be the second methanol-fueled engine conversion that we have undertaken and the first with the Wärtsilä 46F engine. We share a commitment to decarbonize shipping, and the transparent partnership between our three companies for this new build project represents an important milestone along the path to achieving this goal,” said Håkan Agnevall, president and CEO of Wärtsilä.

The ship’s total powerplant is comprised of the two converted 8-cylinder Wärtsilä 46F engines that are capable of operating on methanol, as well as two 12-cylinder Wärtsilä 46F engines and one Wärtsilä 32 engine.

“As we innovate our ship design and offerings, we’re also focused on equally evolving the fuel and technology landscape that powers them,” said Jason Liberty, president and CEO of Royal Caribbean Group. “By incorporating tri-fueled engines, we are ensuring that as alternative, low-carbon-based solutions become more viable, our ships will be ready to adapt and drive the industry forward to a more sustainable and net zero emissions future.”

Celebrity Xcel’s next milestone is its commissioning, scheduled to take place early this fall. The ship is expected to be delivered to Celebrity in October and will sail its first season out of Fort Lauderdale, Fla. to Caribbean destinations before moving to Barcelona and the Mediterranean in 2026.

And this symphony of design and engineering is about to continue. Just after my tour, the company announced that it has contracted with Chantiers de l’Atlantique to build a sixth, yet-to-be-named Edge Class ship in Saint-Nazaire with a delivery date of 2028.