RTX Technology Research Center and Honeywell Aerospace among winning team leads.

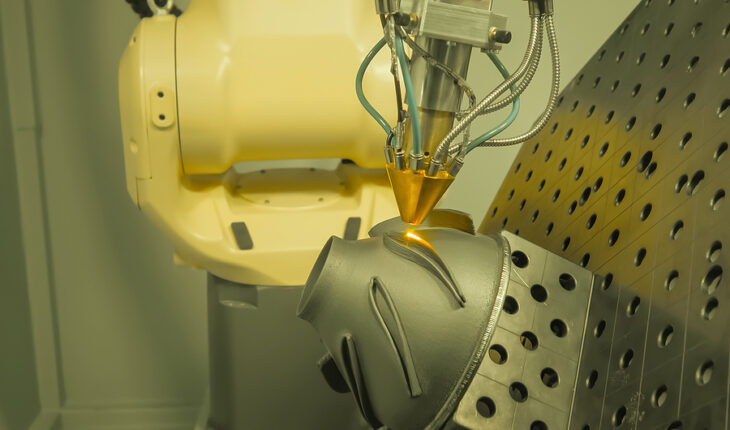

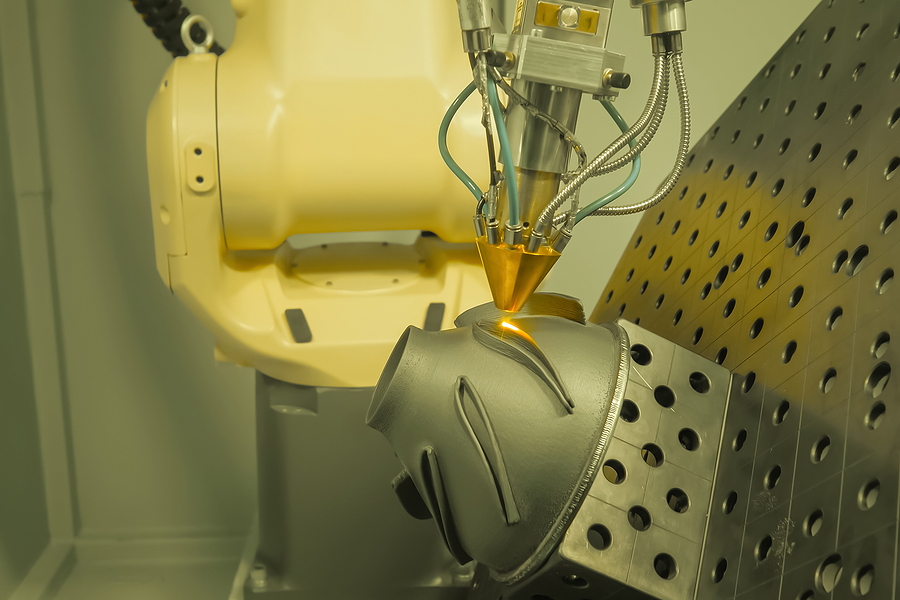

The winners of a project call funded by the Office of the Secretary of Defense Manufacturing Technology Program (OSD ManTech) and administered by America Makes and the National Center for Defense Manufacturing and Machining (NCDMM) are each aiming to improve a different aspect of metal additive manufacturing (AM), with a focus on enhancing forging, casting and tool selection.

The name of the project call could give NASA’s acronyms a run for their money: Improvements in Manufacturing Productivity via Additive Capabilities and Techno-Economic Analysis 2.0 (IMPACT 2.0). Its aim is to demonstrate lead time, productivity, and yield improvements to casting and forging operations us AM technologies.

“For nearly two decades, challenges related to capability and capacity have significantly impacted the U.S. casting and forging industry, creating obstacles in sourcing essential components for critical military equipment and support platforms,” said John Martin, Research Director at America Makes in a press release.

The winners for the forging half of the project call are as follows:

The RTX Technology Research Center will lead Collins Aerospace, the University of Pittsburgh and Camarc in maturing and promoting methods to add functional surfaces and complex geometric features to forgings.

Honeywell Aerospace will lead Lightspeed Concepts and the American Foundry Society, while the Youngstown Business Inclucator will lead a laundry list of businesses and universities in disseminating leading practices and promoting the adoption of 3D printed sand molds and cores.

Finally, the University of Arizona Investment Casting Institute will lead PADT and 3Degrees in a building a techno-economic analytics tool for the selection of metal part manufacturing processes.

On the casting side:

Skuld, DDM Systems, and Renaissance Services will lead their respective teams in a rapid casting demonstration challenge.

“Addressing these challenges is crucial for defense and economic stability,” Martin added in the same release. “While many additive manufacturing technologies can enhance casting operations and have proven effective across other sectors of the supply chain, augmenting and scaling these capabilities while testing them in real-world demand situations is essential. The IMPACT 2.0 project call is designed to pinpoint the strengths and limitations of these integrated manufacturing approaches. This initiative will empower our members and project teams to research, develop, and execute cutting-edge solutions in the casting and forging sector, a strategic move to mitigate supply chain risks that pose a threat to both the nation’s defense and economy.”