Use of the latest advancements in the material sciences is essential for the military to shield the warfighter. Key among them are materials capable of thoroughly transferring harmful heat away from sensitive electronic components, especially in harsh environments.

The next generation of technology in the military, such as high-powered radar jamming systems and hypersonic weapons, requires a large amount of processing power. As a result, processors in this technology contain many heat-generating components. Design engineers must find ways to reliably transfer and dissipate heat from these components to ensure the overall systems continue to operate effectively. In commercial applications, thermal management failure can mean a faulty smartphone. In the military, it can mean mission failure and even the loss of life.

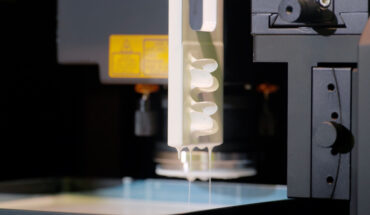

Thermal management in these cutting-edge systems is multifaceted. It includes hardware such as heat sinks and liquid cooling devices – but also thermal interface materials (TIMs). Thermal interface materials transfer heat from hot components, such as transistors in chip packages, to

cooling hardware. They come in different forms, including pads, putties, phase-change materials, thermal greases, and thermally conductive insulator materials. For the military, reliability is the watchword. To maximize reliability, TIMs need three characteristics:

- Wide operating temperature range: The environments in the processors that drive the military’s most advanced technology are harsh and feature extreme and frequent temperature spikes and dips. TIMs therefore must operate reliably in an environment where temperatures can hit 300 degrees Fahrenheit and drop in short order to -50degrees Fahrenheit. This temperature cycling can take a toll on TIMs. Engineers therefore require TIMs designed to withstand these regular temperature fluctuations over a long period of time.

- Durability to withstand harsh substances: TIMs in military applications may rest near harsh liquids or vapors (jet fuel, missile fuel, deicing fluid) that can eat away at the silicone base of these materials. Engineers need to therefore design in a way that shields TIMs and their edges from exposure to harmful substances while also looking to TIM manufacturers to continue exploring the use of more durable materials.

- Resistance to deterioration: Outgassing in TIMs can hinder the performance of optical lenses, and NASA has stringent outgassing requirements. Manufacturers can use a post-cure process to minimize outgassing. Further, if silicone breaks down and “bleeds,” it can hinder the adhesiveness of surrounding surfaces. Design engineers must pay close attention to the formulation of materials within a TIM, which determines its level of resistance to these forms of deterioration.

Materials science creativity is the key to ensuring TIMs meet the evolving needs of military and aerospace design engineers. At Laird, we are constantly adjusting the material makeup of TIMs to enhance temperature stability and prevent outgassing and bleed from the interface. We also tap robust thermal modeling and testing capabilities to measure the effectiveness of TIMs and devise custom solutions for military applications.

To meet the military’s stringent requirements and enable effective thermal management in new, advanced systems, design engineers also need to adopt a system-level design approach. This approach allows engineers to account for all possible thermal and electromagnetic challenges and address them together, early in the design process. It’s well past time to move away from the model of siloed EMI and thermal teams addressing these issues discretely. Signal and heat issues are increasingly intertwined, and space within processors is limited. Therefore, design engineers need to come together to devise creative and space-saving solutions to these increasingly complex challenges.

Though every industry seeks innovation, the push toward the cutting edge is amplified within the U.S. military. After all, the military is in a constant race for supremacy against adversaries around the world – and the stakes are high. Therefore, design engineers are always working to push the boundaries of performance in military technology. But as warfighting capabilities advance, thermal management challenges grow. Military design engineers therefore need to tap into the latest materials science innovations and improve their internal design processes. Reliable thermal management is one piece of the continued advancement of electronics systems in the military – but it’s a crucial one. And TIMs play an essential role in the effort to manage heat in next-gen military technology. To ensure the U.S. military stays a step ahead of its enemies, the industry needs continual improvements in the makeup and capabilities of TIMs.

Learn more about Laird Performance Materials from TTI, Inc.

Sponsored Content by Laird Performance Materials and TTI, Inc.