High-fidelity simulation is a key factor to ensure that simulation can be used as evidence in certification processes

PITTSBURGH, PA, Dec 30, 2024 – Ansys, Kontrol, and TÜV SÜD have announced in collaboration with Microsoft the launch of a virtual homologation toolchain — a cutting-edge solution designed to redefine how automotive manufacturers meet global regulatory compliance and safety standards. This powerful digital platform combines high-fidelity simulation technology with industry-leading expertise to streamline certification processes, accelerate market access, and ensure the highest safety standards for vehicles and components worldwide.

A Collaborative Innovation for the Automotive Industry

The Virtual Homologation Toolchain integrates advanced technologies and industry expertise from:

- Microsoft: Providing the secure Microsoft Azure cloud platform infrastructure and AI-powered analytics to drive scalability and collaboration.

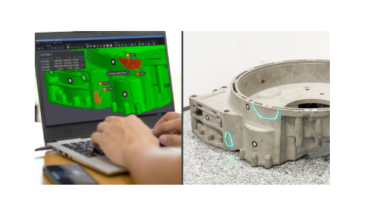

- Ansys: Delivering simulation tools for virtual safety and performance testing, ensuring results are as reliable as physical testing.

- Kontrol: Offering advanced compliance management solutions for seamless regulatory adherence.

- TÜV SÜD: Bringing decades of knowledge in regulatory compliance, homologation and security in road safety worldwide.

Key features of the virtual homologation toolchain include:

- High-fidelity Simulation for Safety Compliance: The Ansys AVxcelerate Autonomy platform virtualizes compliance and safety testing, and is optimized for accuracy and speed, ensuring results meet rigorous global regulatory requirements.

- Cloud-Based Collaboration: Powered by Azure, the platform enables seamless massive acceleration due to AI and major compute power.

- Expert Oversight: TÜV SÜD checks that vehicle simulation and virtual testing outcomes are accurate, reliable, and fully compliant with international regulatory frameworks, including UNECE requirements.

- Automated Compliance Management: Kontrol’s tools provide real-time tracking of regulatory changes and ensure continuous compliance through every stage of development.

Transforming Automotive Homologation

The toolchain addresses critical challenges faced by the automotive industry. This includes the rapid evolution of safety requirements, the emergence of autonomous vehicles, and the regulatory need to show that the digital driver is equal to or safer/more compliant than human drivers. High-fidelity simulation enables engineers to test robust scenarios and edge cases, including incident-free driving for 10^8km. Its key benefits include:

- Significantly reduced Time-to-Market: Accelerate certification timelines with high-fidelity simulation and automated digital processes.

- Cost Efficiency: Reduce reliance on costly physical prototypes by replacing them with validated, physics-based alternatives.

- Improved Safety and Quality: Detect compliance risks early in the design phase, ensuring robust safety performance.

- Global Regulatory Coverage: Navigate complex regulations with TÜV SÜD’s oversight and Kontrol’s compliance monitoring.

Driving the Future of Mobility

“This collaboration brings together a diverse set of technology and regulatory expertise to drive innovation in the automotive industry,” said Shane Emswiler, senior vice president of products at Ansys. “The inclusion of high-fidelity simulation ensures that manufacturers can rely on virtual testing as a secure and predictively accurate alternative to physical trials, paving the way for faster, safer innovation.”

“TÜV SÜD’s pivotal role ensures that the virtual homologation outcomes meet stringent international regulatory requirements,” said Patrick Fruth, chief executive officer of TÜV SÜD division mobility. “By checking the credibility of the simulation, TÜV SÜD leverages its assessment expertise to validate test methods as compliant with regulatory requirements and standards.”

For more information, please visit ansys.com.