Optimal parameters and blazing fast simulations for powder bed fusion, sustainability all around, and 3D printing makes chess even better.

Welcome to the second edition of the engineering.com Additive Manufacturing Progress Update, a monthly column focusing on the latest in 3D printing research and business – with a little fun thrown in at the end. Here’s last month’s column, in case you missed it.

Let’s get to it!

Additive manufacturing research review

In this section, we review recent additive manufacturing research papers published in open-access formats, summarizing each article with comments from the researcher(s) when possible. We also include links to the full texts for further reading.

3D printing ribbed concrete ceilings

There’s a tendency to think additive construction is confined to large, gantry-style machines that extrude concrete in layers to produce entire structures, but there’s more than one way to utilize 3D printing in construction. Case in point: three researchers from the Institute of Structural Concrete at RWTH Aachen University in Germany have published a case study on creating modular ribbed concrete ceilings using a fabrication system that combines extrusion-based 3D concrete printing, robotic casting and carbon fiber reinforced polymer (CFRP) grids for support.

The ceilings consist of two modules: a point-supported slab-column connection module and an inter-column support strip module, both of which use topology optimization to reduce the amount of material required by 40-50%.

The trouble with these structures is that they typically require too much manual effort to make them practical in most projects. That’s where the researchers’ digital manufacturing setup comes in: by automating the printing, casting and reinforcement steps required to fabricate ribbed ceilings, they not only reduced the manual effort required, but also enhanced the structures’ load-bearing capacity.

Comparing pre- and post-heating of carbon fiber reinforced polyamide 6

Understanding the effects of temperature variations before, during and after the 3D printing process is vital to ensuring consistency in the quality of additive components. That’s why engineers from the Norwegian University of Science and Technology and the University of Bristol took a closer look at how in-lay infrared pre- and post-heating impacts carbon fiber reinforced polyamide 6 (PA6-CF) in a material extrusion process.

“Engineers should achieve as high a temperature as possible on the substrate layer without losing structural integrity in the part. If you have a local heater, boost the temperature around the fusion area. If you have a heated chamber, increase the chamber temperature and heat the entire part. Or if you have neither, reduce the layer-time to maintain the residual temperature from the previous layer. A combination of all three will naturally also work. In addition, measure and find the optimal layer temperature for each material you are working with for future reference. Annealing the part properly after manufacturing will also be beneficial.“

– Ole S. Nesheim, PhD Candidate, Norwegian University of Science and Technology

The researchers compared various combinations of no heating, pre- and post-heating, as well as different printing speeds, but consistent wall thickness and layer height. What they found was that pre-heating was more beneficial for part strength than post-heating at higher speeds while the converse was true for lower speeds. The researchers suggest that the thermal model they have developed could be used to improve material strength in engineering plastics, yielding near isotropic, complex components.

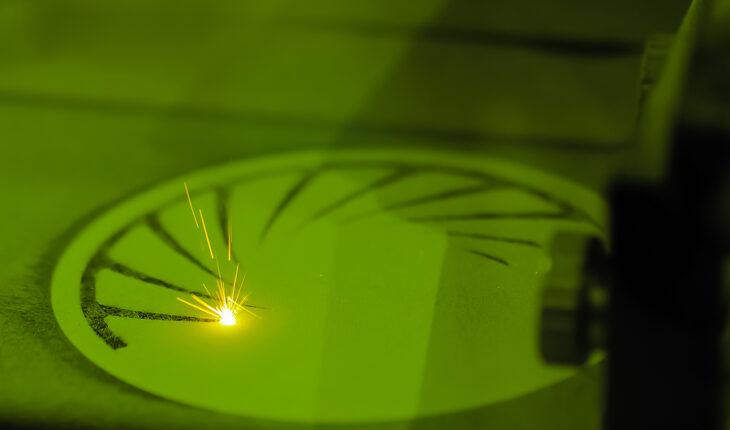

The effect of high scan speeds in laser powder bed fusion

Laser scanning speed is one of the key variables in laser powder bed fusion (L-PBF), affecting build time as well as the microstructure and mechanical properties of 3D printed parts. Stainless steel 316L is one of the most popular materials for metal L-PBF, so it makes perfect sense to investigate how laser scan speed affects the quality of 316L parts. To that end, researchers from the University of Applied Science Muenster and the University of Siegen in Germany investigated the manufacturing limits of this material and process.

What they found was that scanning speed has a major impact on both grain size and surface finish. Aiming for optimal build up rates and relative densities, they discovered that a laser power of 285 W and a scanning speed of 1250 mm/s results in parts with relative densities of 99.2%. The high scanning speed also resulted in a higher cooling rate, which in turn leads to smaller grains.

Open machine learning model for thermal analysis in laser powder bed fusion

While empirical research like the previous paper is undoubtedly necessary to gain a better understanding of additive manufacturing (AM) processes, engineering simulation is equally important in providing the tools needed to enhance the quality and consistency of 3D printed parts. Continuing on the topic of L-PBF, two researchers at the Empa Swiss Federal Laboratories for Materials Science and Technology have been looking into ways to reduce the computational cost of simulating this process.

Machine learning is showing promise as a way to improve engineering simulation for AM and the Empa researchers are following that trend with the twist of treat the moving laser heat source as a sequence of pulses. Using a pair of feed-forward neural networks (FFNNs), they implemented their pulse approach and found that the paired networks can replicate temperature profiles or predicted temperature histories of finite element simulations in less than a second. As an added bonus, their models and scripts are openly available on GitHub.

AM biomedical metals review

With the exception of aerospace, no industry has embraced additive manufacturing as fully as the medical device industry. As a result, the state of AM applications in biomedical implants has been advancing rapidly in recent years, so much so that it can be difficult to keep up with all the new developments.

Fortunately, a team of engineers and physicians from Xi’an University of Science and Technology, Shanghai Jiao Tong University, Shanghai University of Electric Power, and Youjiang Medical University for Nationalities in China, as well as Edith Cowan University in Australia, have just published an extensive review of the current state of medical implant materials, processes and challenges involving AM. Of particular note is the section on 4D printing and its applications in soft robotics and NiTi shape memory alloys.

Additive manufacturing market matters

In this section, we discuss notable changes in the share prices of publicly traded additive manufacturing companies, with additional comments on major contracts and other announcements from both public and private companies. Note that these are subject to the latest available data as of February 28, 2025 at 9am EST.

| Company | Ticker | Current Price | MoM % Change | YoY % Change |

| 3D Systems | DDD | $3.49 | -6.4 | -18.3 |

| Desktop Metal | DM | $2.18 | -12.8 | -63.1 |

| Markforged | MKFG | $2.56 | -11.7 | -62.4 |

| Materialise | MTLS | $5.21 | -39.8 | -4.9 |

| Nano Dimension | NNDM | $2.10 | -11.4 | -27.6 |

| Stratasys | SSYS | $10.65 | 13.4 | -14.5 |

| Protolabs | PRLB | $39.30 | -6.4 | 5.9 |

| Xometry | XMTR | $27.35 | -21.7 | -9.4 |

| S&P 500 | SPX | $5,861.57 | -3.5 | 15.7 |

Notable shifts in AM share price

There was disappointing performance all around this month for the six publicly traded AM suppliers listed above. Only one – Stratasys – has seen a positive shift since January, likely buoyed by the $120M equity investment from Israeli private equity fund Fortissimo Capital, announced on February 2. That investment pushed Fortissimo from holding 1.5% of the company’s issued and outstanding ordinary shares to 15.5% and gave Fortissimo a seat on the Stratasys board of directors.

Despite the increase in Stratasys’ share price, the share prices of public traded AM suppliers are down 11% on average month-over-month, nearly four times the decline in the S&P 500. Materialise saw the biggest month-over-month decline following the release of its financial results from 2024, with the company’s software and manufacturing revenue down by 1.1% and 13.3%, respectively.

Year-over-year, the picture looks even worse, particularly for Desktop Metal, Markforged and, to a lesser extent, Nano Dimension. It’s difficult to see those three names being at the bottom of the chart as mere coincidence. With the trial date set for Desktop Metal’s litigation against Nano Dimension over the latter’s proposed acquisition of Markforged, there will no doubt be further challenges for the three companies in the weeks ahead. Even with Desktop Metal’s dismissal of Markforged as a defendant, the latter losing its general counsel suggests that its troubles are far from over.

Between the two largest publicly traded AM service bureaus, Protolabs and Xometry, the averaged outlook appears somewhat more optimistic. While Protolabs’ revenue was down 2.6% in Q4 of last year, Xometry reported a 16% increase in the same period. Moreover, revenue for the Protolabs Network – the company’s direct competitor to Xometry – saw a 17.9% increase.

All of this suggests that the AM industry is facing the same challenge as the broader market: uncertainties about international trade stemming from the conflict between the globalization of supply chains and the nationalism within certain governments. As a highly specialized, highly advanced industrial segment, additive manufacturing is likely to feel the effects of this uncertainty more strongly than other areas of manufacturing due to simple risk aversion. For that reason, it seems likely that the biggest wins for AM in the near term will be in areas where it’s already at an advantage, such as medical device manufacturing. The relatively better performance of the AM service bureaus coupled with uncertainties in international trade also suggest that further advantages can be gained through its benefits to supply chains.

AM business developments

A few other noteworthy events took place in the AM business world over the past month.

3D Systems’ founder, Charles “Chuck” Hull was elected to the National Academy of Engineering for his invention of stereolithography and the subsequent development of the AM industry. While Hull is only one among 128 new inductees, it’s worth noting how few engineers have been elected on the basis of developing an entire industry – Morris Chang, Steve Wozniak and Joseph Engelberger are the only others that spring to mind. An august group to be part of in an already esteemed community, so congratulations to Mr. Hull.

Elsewhere, ‘sustainability’ appears to be the watchword in AM this month, starting with ASTM International receiving $2.1M in funding from the Office of the Under Secretary of Defense for Research and Engineering to lead research on AM’s sustainability and environmental benefits.

Then there was the announcement that the Multi-Scale Additive Manufacturing Lab at the Canadian University of Waterloo would receive a $5M CDN investment from the Federal Economic Development Agency for Southern Ontario to support the launch of the Consortium for Sustainable Scale-up in Metal Additive Manufacturing.

Meanwhile, EOS and Stratasys both announced milestones in sustainability, with the former introducing a 100% recycled aluminum powder and the latter receiving a Silver sustainability rating from Ecovadis, which apparently puts it in the top ten percent of Ecovadis’ rankings.

Granted, these aren’t all private businesses, but the fact that AM’s sustainability is being touted across so many different organizations should not be discounted for that alone. Whether this will prove to be a true competitive advantage or just table stakes remains to be seen.

3DPTV

You’ve made it this far, so here’s a little treat for the end of our latest column.

If you’re a fan of chess as well as 3D printing, you’ll probably appreciate this video from Works By Design, in which the author takes us through his six-month journey of designing and building a pawn that transforms into a queen when it reaches the other side of the board. The video came out back in November, but it’s such an intriguing concept that it’s well worth your time. Watch it below:

That wraps up the latest edition of our Additive Manufacturing Progress Update.

Send your questions, comments or complaints to me at [email protected], and they might just appear in next month’s column.