Streamline your product lifecycle with integrated systems.

SAP has sponsored this post.

In an era of rapid technological change, businesses are under increasing pressure to stay competitive. Managing complex product development processes while ensuring seamless communication and real-time data flow is one of the most significant challenges. Traditional, isolated systems are no longer sufficient. Instead, organizations need integrated solutions that connect every facet of their operations — from product development and procurement to sales and customer service — into one cohesive ecosystem.

Seamlessly integrating product lifecycle management (PLM) and enterprise resource planning (ERP) solutions delivers on the mission critical requirement to manage product data across the enterprise. By breaking down silos and enabling smooth data flow between systems, companies can simplify operations, promote innovation and foster better collaboration.

Let’s dive into why integrated PLM and ERP systems matter, and how they can drive your business forward.

Why Seamless Integrations Matter

You might be asking yourself: Why is integration such a critical factor for business success? The answer lies in the tangible benefits that connected systems bring to your product development and operations. Let’s break down those key advantages:

1. Data consistency across platforms

Inconsistent data is a costly problem. When information is scattered across different systems, errors and delays are almost inevitable. Companies need to ensure that product data is synchronized across all platforms — whether it’s design, procurement, manufacturing or sales. Bi-directional data exchanges mean that changes made in one system are automatically reflected in others, ensuring everyone, from engineers to suppliers, works with the same accurate, up-to-date information. Real-time data consistency helps minimize errors, accelerate decision-making and keep your processes running smoothly.

2. Streamlined collaboration

Effective collaboration can make or break your product development process. Internal and external teams need to be connected with seamless communication that provides access to real-time data. With bi-directional data exchanges, teams can confidently share information knowing it remains consistent across all platforms. No more long email chains, fragmented conversations, or delayed approvals. Teams can collaborate more efficiently, speeding up development cycles and reducing time-to-market. Integrated platforms also make it easier to work with suppliers, partners and customers — creating a more connected and nimble business ecosystem.

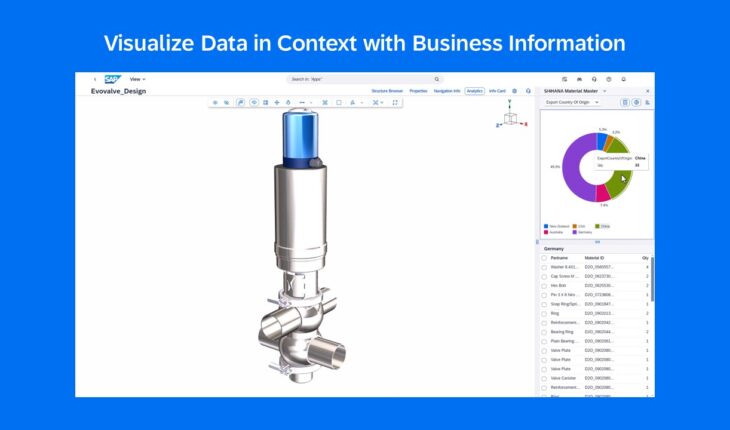

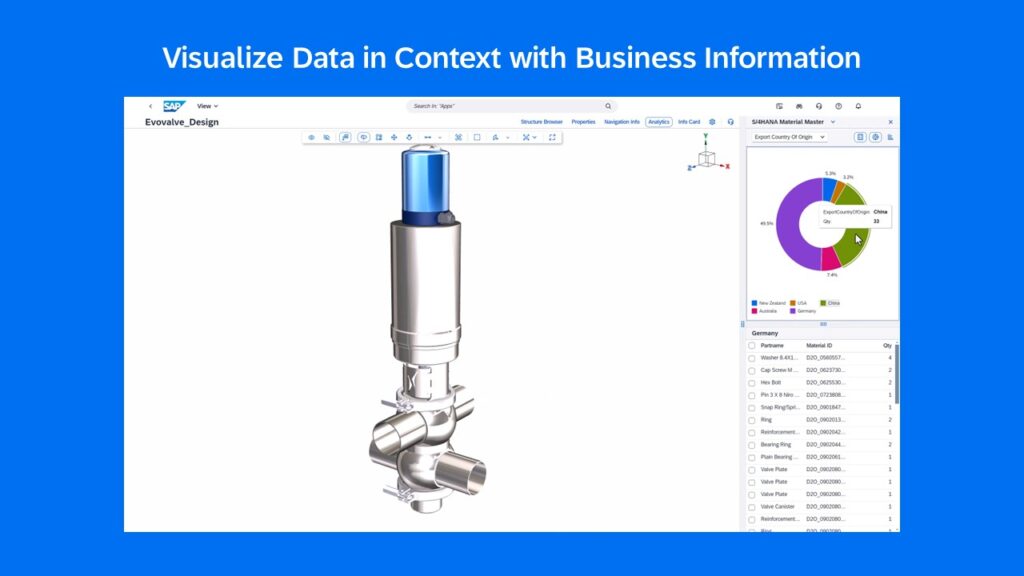

3. Enhanced product experience

Today’s customers expect more than just quality products; they demand engaging product experiences. Businesses want to leverage interactive 3D models, designs and detailed visualizations. Thanks to bi-directional data exchanges, the most current product data is always available, ensuring that designs and models reflect the latest specifications. This enhances customer understanding, engagement and helps them make informed purchasing decisions. The result? Higher customer satisfaction, stronger loyalty and a competitive edge in the marketplace.

4. Automation and efficiency

Automation is a powerful tool for boosting productivity. Organizations require the automation of key processes, such as: approvals, order processing and workflow management. Bi-directional data flow between systems also means that these automated processes are always working with the latest information. With real-time visibility into tasks and operations, you can quickly identify bottlenecks and inefficiencies. This proactive approach helps streamline workflows, reduce manual effort and ensure that your teams stay focused on high-value activities.

Three high-value scenarios for effective PLM integrations

When PLM solutions integrate with other core business tools, companies can better manage product data, collaborate efficiently and make faster, more informed decisions. Here are three high-value examples where integration can drive significant business innovation:

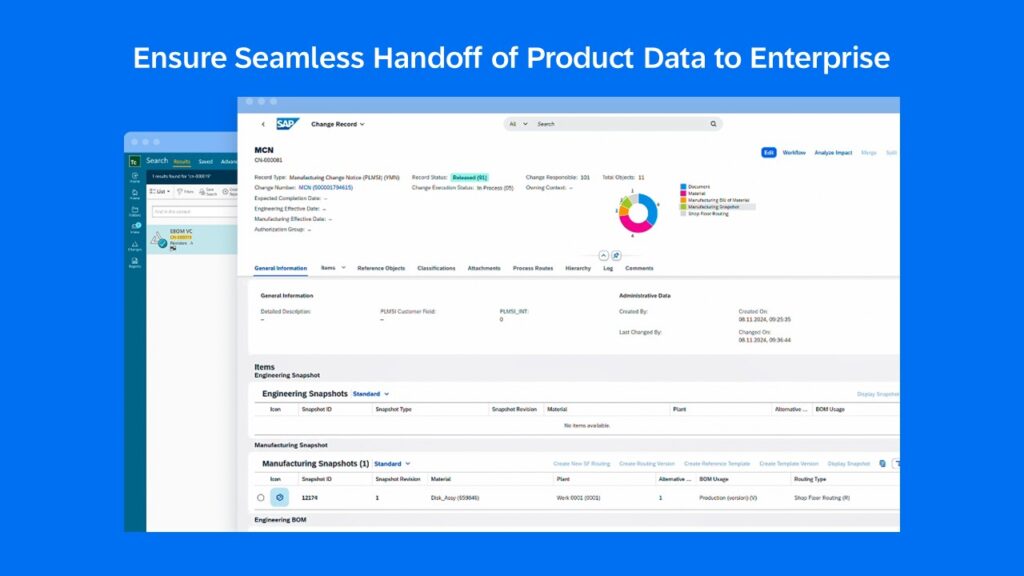

1. Connect your data: integrating PLM with ERP systems

When PLM systems integrate with ERP platforms, they enable real-time synchronization of product and business data. For example, manufacturing teams can access the most up-to-date bills of material (BOMs) directly from the PLM system, ensuring accurate production. Service teams can use design data, like 3D models, to troubleshoot and maintain products effectively. Bi-directional data ensures consistent and reliable information throughout the product lifecycle, resulting in products that meet quality standards from design to delivery.

2. Connect to platforms: integrating third-party PLM systems

Businesses often rely on specialized third-party PLM systems, such as Siemens Teamcenter, Dassault Systèmes 3DEXPERIENCE or Autodesk Vault, to coordinate various aspects of product development. Integrating these tools with enterprise systems ensures that product data flows seamlessly fostering collaboration and maintaining data integrity.

This integration also allows design teams to work in their preferred tools while ensuring the data is consistently available and accurate. For instance, product designs created in a third-party PLM system can be transferred into ERP for direct use in downstream supply chain processes, ensuring a smooth handoff of information and reducing the risk of miscommunication.

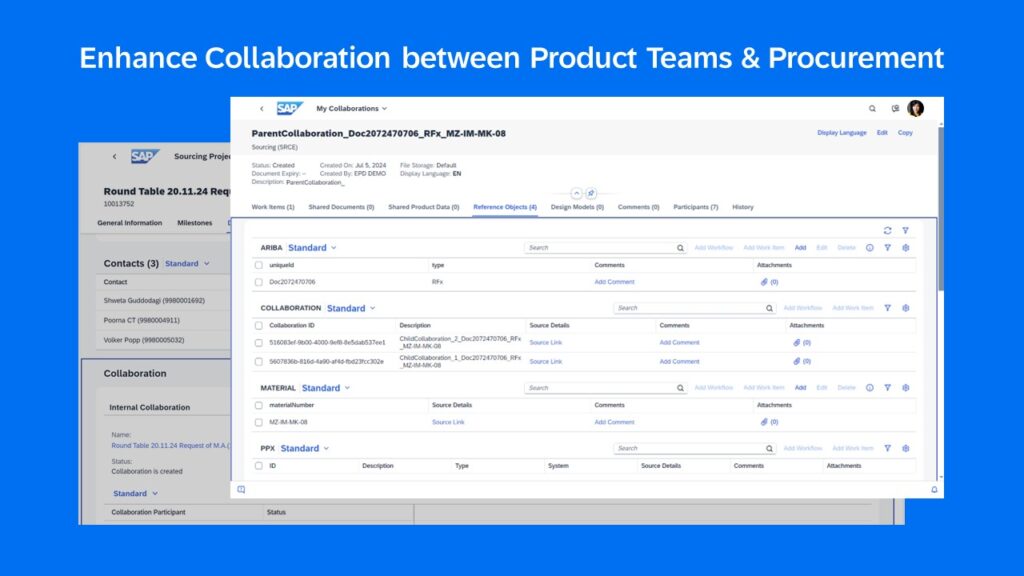

3. Connect your ecosystem: integrating PLM with supplier networks

Close collaboration with suppliers during sourcing and procurement can significantly increase business success. Having an integrated digital platform where the latest engineering, development and manufacturing information is securely shared with suppliers, enables companies to eliminate the need for endless email exchanges, phone calls and manual updates.

For example, material specifications, quality standards and design changes can be exchanged with suppliers in real-time, ensuring everyone is on the same page. Companies can onboard suppliers faster, improve compliance and speed up the procurement processes. The outcome? Smoother supplier collaboration, faster time-to-market and improved product quality.

Embrace integration for operational excellence

Integration isn’t just a technical convenience — it’s a strategic necessity. Seamlessly connected systems empower businesses to streamline product lifecycle processes, improve collaboration and make data-driven decisions with confidence. In a world where complexity is the norm, integration provides the clarity and flexibility needed to stay ahead of the curve.

When product data flows across design, engineering, procurement and production, the entire organization benefits. Teams can collaborate in real time, minimize errors, manual tasks and respond faster to market demands. Suppliers and partners stay aligned, ensuring smooth handoffs and consistent communication. And with automated workflows, bottlenecks and inefficiencies can be identified and resolved before they impact productivity. Integrated systems also allow you to deliver quality products and exceptional experiences that build loyalty.

Forward-thinking businesses recognize that tight integration is the key to unlocking future growth and resilience. To learn more about how SAP can support your product development processes, we invite you to explore our other articles in this series, visit our website or check out our newest website for PLM Systems Integration.