Companies must launch more products to be competitive, but how can they track it all?

Dassault Systèmes has sponsored this post. Written by Ajay Prasad, Worldwide ENOVIA Industry Process Expert, Dassault Systèmes.

Adopting a data-driven and deliverables-based project management approach establishes a digital thread between product and project data. This enables real-time project execution tracking and analytics, leading to enhanced efficiency, accuracy and execution.

Across industries, companies looking to launch products are executing several new product development (NPD) projects at any given time. With ever-increasing customer expectations, customized product experiences and complex business models run by global teams — including suppliers — executing NPD projects is mission-critical to reducing costs and increasing a company’s bottom line.

With several competing products available in the market, the speed with which a company can launch a product is a huge factor in determining the product’s success. Companies need to launch more products by executing more NPD projects, simultaneously and with the same number of resources. Historically, this has been a complex challenge. However, it is now possible through evolutions in project execution, performance monitoring and product lifecycle management (PLM).

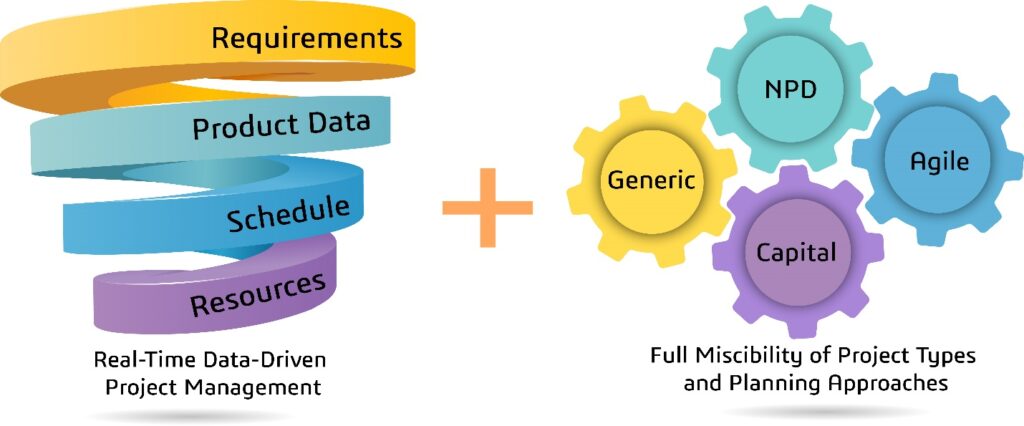

When discussing project management, the schedule is often considered to represent the entirety of a project. However, the reality is that the schedule alone does not encapsulate all aspects of a project, especially after launch. So, let us consider the different facets of an NPD project:

- Requirements (the Why): the motives and goals of the project.

- Product data (the What): the artifacts, deliverables and output of the project.

- Schedule (the When): the timeline by which the project tasks and milestones are due.

- People (the Who): the project teams who are assigned to complete each task.

These facets of an NPD project are typically managed in different enterprise systems, each in its own silo. This results in many non-value-added activities for the entire project team, as the information across these enterprise systems must be manually reconciled to understand the project’s status. This process is inherently error-prone leading to rework, idle time and overloaded resources. All of these challenges reduce the speed to market.

Approximately 30% of a project team’s time is spent on non-value-added activities. If this time was significantly reduced or even eliminated, NPD projects could be executed faster. Companies could launch more products faster with the same resources, making them more competitive.

At a high level, these challenges can be solved by bringing all facets of an NPD project — requirements, product data, schedule and resources — together into one PLM system. With a platform-based approach, organizations work off a single database and connect their business processes. This allows the facets of an NPD project to be digitized, directly linked to one another, viewed and updated in the context of the digital (or virtual) twin. This connects the dots throughout the NPD process with real-time, data-driven project status updates.

Simply put, managing project information on a PLM system composed of loosely integrated disparate tools doesn’t solve the root of the problem. This is because data needs to be reconciled. Reconciling data programmatically does provide incremental benefits over a manual reconciliation.

However, in this scenario data is still replicated across systems and product development teams are still working in silos. This does not foster the organizational alignment necessary for project success. There is a heavy dependency on IT integrations and the front-end glue that sticks everything together hides the underlying complexity. A robust PLM system with a platform-based approach and single database, however, effectively addresses these challenges, providing a clear path to project success.

Historically, the primary project management methodologies used were “waterfall” and “agile” approaches. A waterfall approach is more suited for companies launching products in a phase-gate manner with predefined milestones and tasks. Typically, companies with a wealth of project execution experience use this approach. Examples include automotive, industrial equipment, energy, marine, aerospace and defense companies.

The agile approach is suited for companies that follow iterative development, where the product requirements keep changing. This mandates a high degree of flexibility. Companies that do not follow a phase-gate approach to product development instead implement an iterative process that starts with a minimum viable product (MVP) definition. Further development is done to bring the MVP towards a final product. Examples of companies that use this approach tend to specialize in software development and hi-tech devices.

Over the last decade, the amount of software going into products has increased exponentially. Software is no longer limited to high-end luxury EVs. Even internal combustion engine vehicles such as the Ford F-150 have over 150 million lines of code. Due to this evolution in products, companies that typically followed a waterfall approach are now looking to implement a “hybrid project management system,” where the waterfall approach is still used to define the steps and milestones. Meanwhile, an agile approach manages the software development that goes into the product. These two methodologies need to work with one another throughout the NPD process.

Characteristics of a PLM system that can handle this hybrid approach, are:

Platform based

- Avoid replicating data across disparate systems by managing all facets of NPD projects in one system, working off a single database connected with a business process.

- Foster adoption of the software as a service (SaaS) cloud for project management anytime and anywhere.

- Focus on organizational alignment toward project success versus micro team processes.

- Permeate through all applications connected to the platform – designers can add project deliverables and update status in the CAD tool.

Data-driven and deliverables based

- Eliminate the inefficiencies of working with files and manual processes.

- Extract the information from files and digitize data with objects, relationships and attributes.

- Link project deliverables, documents, data and more to project tasks, allowing for viewing of the project in the context of a virtual twin.

- Enable invisible governance, where the status of project deliverables is automatically determined, allowing for fact-based verses perception-based reporting.

- Provide real-time data-driven project dashboards to the entire project team so that informed decisions can be taken quickly to steer the project toward success.

Flexible and open

- Allow executing NPD projects with waterfall, agile and team-based planning methodologies all in one solution.

- Allow projects executed as waterfall, agile and team-based planning to be linked to one another.

- Connect to planning solutions that are still used extensively to define an initial project schedule before the project goes live.

- Allow the exporting of project schedules and status to facilitate business needs.

While traditional project management software is focused on building a great project schedule, it does not do much to track the execution of the schedule once the project goes live. These solutions are not designed to manage product requirements, project deliverables, risks, issues and other elements.

Project management on a platform-based PLM system, such as ENOVIA on the 3DEXPERIENCE platform, is focused on fine-grain scope project execution tracking based on deliverables. With a platform-based approach, all project facets are linked and can be visualized and understood in the context of the virtual twin. This, combined with the flexibility of executing different project management methodologies (such as waterfall, agile and team-based planning) all in one solution on a SaaS cloud provides exceptional value to the entire project team throughout the NPD process.

Other key features of ENOVIA on the 3DEXPERIENCE platform include:

Centralized digital live schedule

- With a centralized live schedule, the project leader can make updates to the schedule that are seen instantly by the entire project team, instead of emailing and working with several versions of the file.

Real-time automated task optimization

- This takes away much of the overhead for project leaders to continuously optimize the project schedule as tasks are delayed, added and more.

Product data linked directly to task deliverables

- This allows the entire project team to view the status of tasks and related deliverables all in 3D and understand everything in the context of the digital/virtual twin of the product.

Online task execution and updates

- The entire project team should be able to update tasks and add deliverables online anytime, anywhere, with instant visibility to the rest of the project team.

- The user experience of updating project tasks feels easy and natural.

Online risk and issue management

- Project teams need to be able to define risks in the context of project tasks and milestones.

- Online risk mitigation plans orchestrate risk mitigation activities.

- Project leaders can see the impact of the risk and issues and make necessary changes to project timelines.

Real-time data-driven project dashboards

- Eliminate the non-value-added work of compiling reports on project status with real-time data-driven project dashboards that provide a 360-degree view of the project across all facets.

To learn more, visit ENOVIA at Dassault Systèmes.

About the author

Ajay Prasad, Worldwide ENOVIA Industry Process Expert, Dassault Systèmes.

Ajay Prasad is a product lifecycle management (PLM) professional based out of the metro Detroit area. He has over 21 years of experience and expertise in the design, architecture, development, implementation and technical sales of ENOVIA PLM systems across various industries. Ajay also has a Bachelor of Engineering in Industrial Engineering and Management and a Master of Science in Computer Science. After graduating, he started working as a mainframe professional and later in the area of PLM, implementing and customizing ENOVIA PLM solutions across industries such as automotive, healthcare and industrial equipment. Ajay then worked with customers in India and the U.S. He later worked for Dassault Systèmes in India as a Technical Sales Consultant for ENOVIA PLM software. Ajay returned to the U.S. and joined the ENOVIA Worldwide Center of Excellence team at Dassault Systèmes. Currently, he works as an ENOVIA Worldwide Industry Process Expert with responsibilities that include technical sales of ENOVIA PLM, technical sales teams’ enablement and serves as a liaison between field teams, customers and product R&D in pre- and post-sales situations. He fosters customer success and adoption of ENOVIA PLM software and is the team’s focal point for the ENOVIA Project and Workforce Management suite of applications.