Each of these simulation techniques has its place for fluid problems. Here’s how to pick which is best for yours.

Finite element analysis (FEA) is primarily used to predict how external forces affect solid structures. However, FEA can also be applied to some fluid problems, particularly where the fluid-structure interaction (FSI) is important.

For example, engineers may need to analyze the stress and deformation of an aircraft wing under aerodynamic loads or compute thermal deformation in engine components. FEA is also used when the fluid and structural response need to be analyzed simultaneously, such as interactions between blood flow and artery walls or dam deformations due to water pressure.

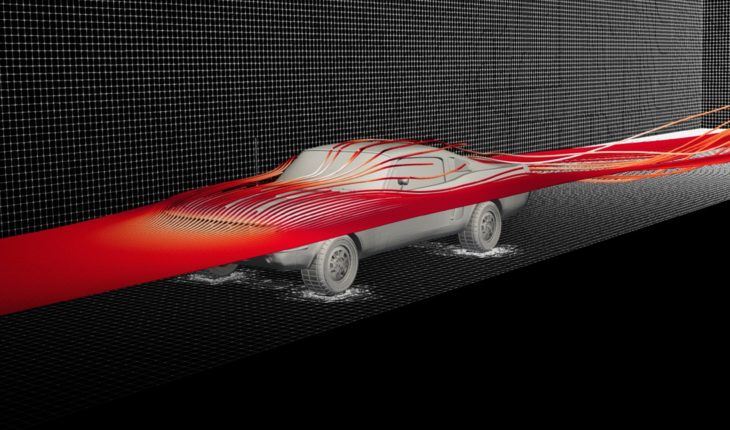

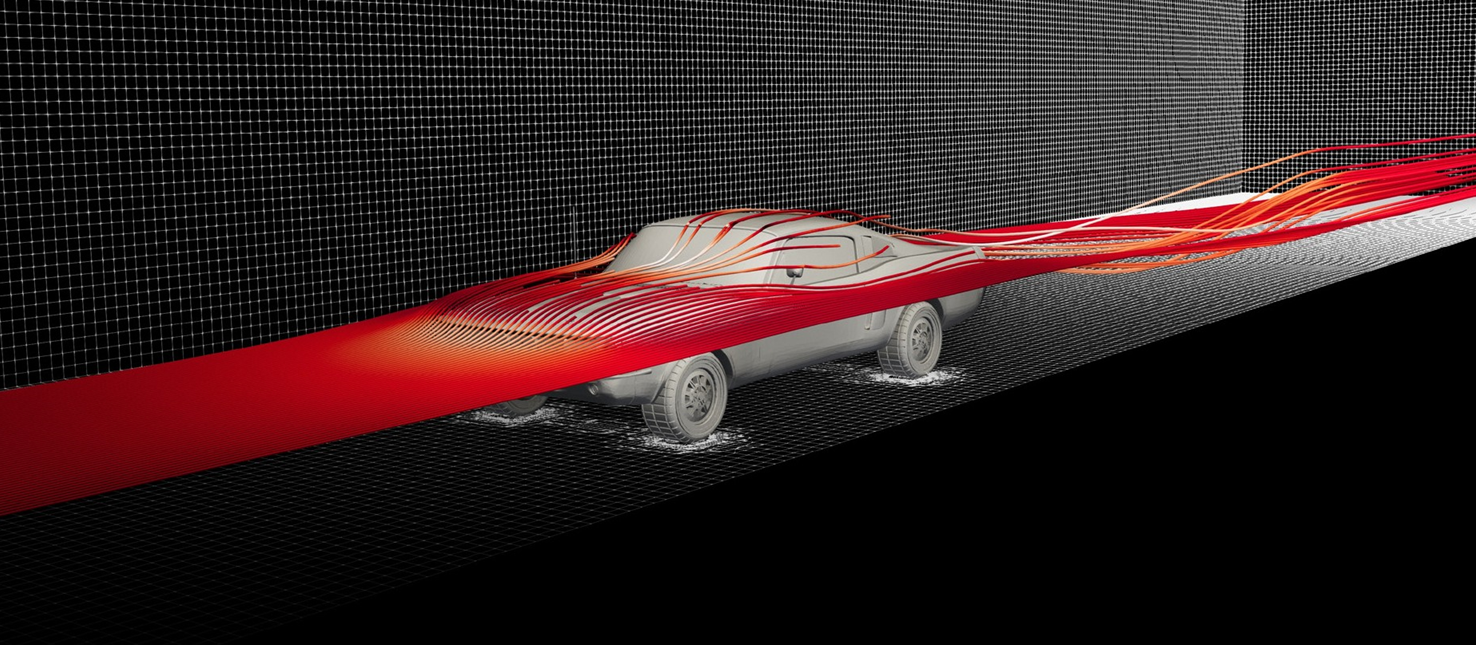

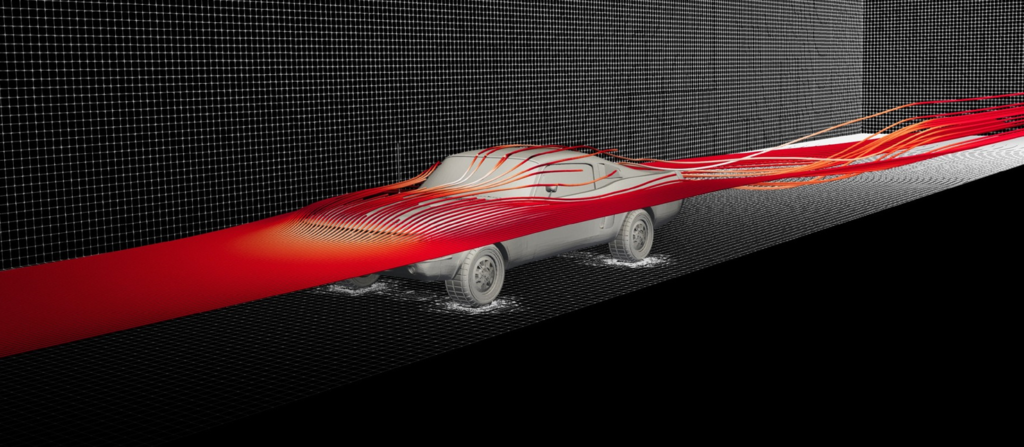

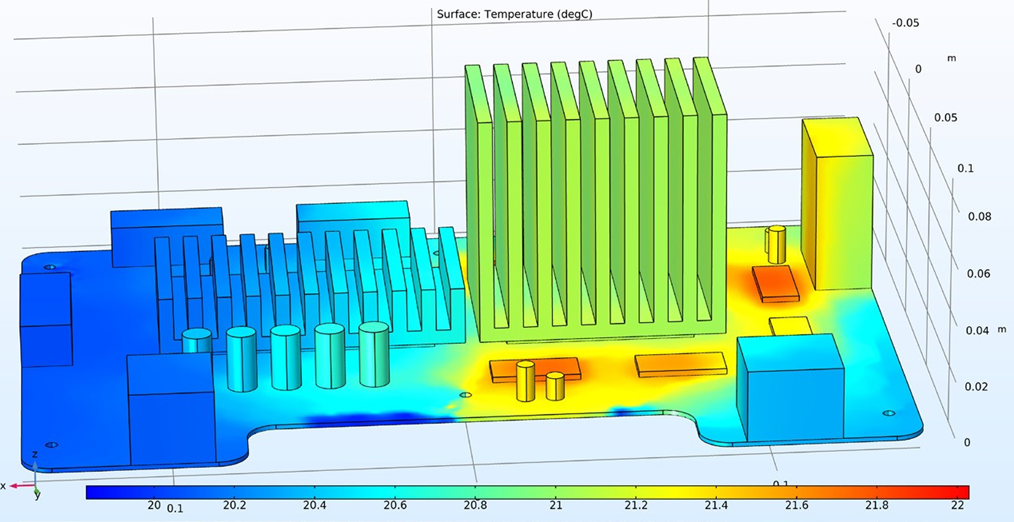

Computational fluid dynamics (CFD) simulation is used when the primary focus is on analyzing fluid flow, heat transfer and related phenomena. This includes the behavior of fluids in motion, such as airflow over a car body or water flow around ship hulls. CFD is also used when analyzing thermal phenomena involving fluids, such as convection cooling in electronic devices and combustion processes in engines.

In cases where fluid flow affects structural integrity and vice versa, an integrated approach using both FEA and CFD might be necessary. For example, aerospace engineers may use CFD to determine the pressure distribution over an aircraft wing and then use FEA to analyze the wing’s structural response to the pressure. Similarly, civil engineers may use CFD to simulate water flow around a pier and compute the hydrodynamic forces, and then use FEA to assess the pier’s structural integrity in response to such forces.

The general rule of thumb is to use CFD when the problem primarily involves fluid behavior, heat transfer within fluids or the interaction between multiple fluid phases, and to use FEA when the focus is on the structural responses to external forces, including those induced by fluid flows, thermal stress and FSIs.

Alternatively, engineers can use multiphysics simulation to solve FSI problems simultaneously.

Multiphysics software includes coupled solvers that can handle the simultaneous and dynamic interaction between fluids and solids and solve the governing equations for both in a synchronized manner. It can also handle moving and deforming meshes to model how fluid changes shape due to structural deformation.

Multiphysics simulation uses either a monolithic or partitioned approach to ensure convergence of the coupled FSI problems. The monolithic approach simultaneously solves the fluid and structural equations in a single system of equations, which can be more stable but computationally intensive. With the partitioned approach, the software solves the fluid and structural equations separately and iteratively exchanges boundary conditions until convergence is achieved.

Coupling methods for the partitioned approach are considered either one-way or two-way data exchanges depending on how the fluid flow and structural deformation affect each other. In a one-way data exchange, the simulation is performed in a particular order, and the results from the first analysis are inputs for the second analysis, which doesn’t affect the first. This is similar to running a CFD simulation to calculate aerodynamic pressure on an aircraft wing and then running an FEA to analyze the wing’s structural response. In a two-way data exchange, the fluid and structure affect each other dynamically, so the simulation runs iteratively and exchanges data back and forth to more accurately represent the coupled behavior.

Overall, the choice between using separate FEA and CFD software, multiphysics software and the simulation approaches and methods depends on the nature of the problem being studied, the required accuracy and the available time and computational resources.