Expansion will include precision CNC machining, custom component manufacturing, and on-demand solutions.

IRVINE, CA and MANNHEIM, Germany, Dec 23, 2024 – Norck has announced a major expansion of its services, focusing on precision CNC machining, custom component manufacturing, and on-demand CNC machining. A key highlight of this growth is the enhancement of Norck’s curated network of select manufacturing partners, ensuring clients benefit from the highest quality standards and consistent reliability.

Complementing its growing capabilities, Norck reaffirms its commitment to personalized, one-to-one engineering and design support, setting it apart from competitors with automated platforms. With a strategic combination of expert guidance and a carefully vetted partner network, Norck is revolutionizing the way businesses approach custom parts manufacturing.

Norck’s Motto: “Prototype. Manufacture. Scale Up. On Demand.”

This guiding principle reflects Norck’s dedication to delivering seamless, end-to-end solutions that meet the dynamic needs of modern industries. From initial prototyping to full-scale production, Norck empowers businesses to innovate and grow with speed and precision.

Expanding a Curated Network of Trusted Manufacturing Partners

Norck’s curated network of select manufacturing partners brings together top-tier facilities specializing in CNC machining, injection molding, and metal 3D printing. Each partner is carefully vetted for quality, reliability, and expertise, ensuring seamless collaboration and superior results.

Key Benefits of Norck’s Manufacturing Partner Network:

- Consistent Quality Standards: Partners are selected based on strict adherence to global certifications such as ISO 9001 and AS9100.

- Diverse Capabilities: Access to advanced manufacturing technologies, including custom CNC machining, custom component manufacturing, and on-demand sheet metal fabrication.

- Streamlined Project Management: Norck acts as a single point of contact, managing every aspect of production and ensuring seamless coordination across its network.

“Our curated network is an integral part of delivering exceptional results to our clients,” said Faruk Guney, CEO of Norck. “By partnering with only the best manufacturers, we ensure that every project meets our clients’ exacting standards. Combined with our one-to-one engineering support, this approach guarantees a superior manufacturing experience.”

Personalized Engineering and Design Support

Unlike platforms that rely heavily on automation, Norck emphasizes a one-on-one collaboration model with clients. This personalized approach ensures that designs are optimized for manufacturability, cost-efficiency, and performance before production begins.

Key Features of Norck’s Engineering and Design Support:

- Dedicated Design Consultants: Clients work with experienced engineers who understand their unique requirements and industry challenges.

- Seamless Iteration: From concept refinement to rapid prototyping, Norck supports clients at every step to perfect their designs.

- Material Selection Guidance: Expert advice to choose the best materials for durability, performance, and cost-effectiveness.

- Feasibility Analysis: Comprehensive evaluations to ensure manufacturability and optimal production outcomes.

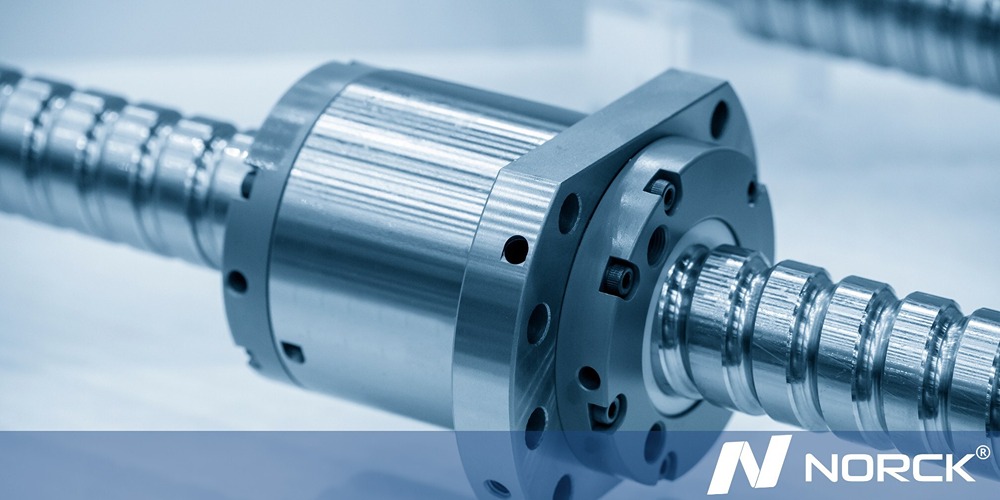

Precision CNC Machining and Custom Component Manufacturing

Norck’s precision CNC machining services are at the forefront of its manufacturing offerings. With a focus on high-quality production and design optimization, Norck delivers custom CNC parts and components that meet even the most complex specifications.

Key Highlights:

- On-Demand CNC Machining: Rapid, efficient production tailored to client needs, from prototypes to large-scale production.

- Wire EDM Services: Precision machining for intricate designs requiring tight tolerances.

- Custom CNC Machining Near Me: Localized support through Norck’s extensive partner network for faster turnaround times and convenience.

Advanced Metal 3D Printing Services

Norck has also enhanced its metal 3D printing services, providing innovative solutions for lightweight and complex custom metal parts. These services are integrated with Norck’s engineering support to ensure clients achieve the perfect balance of creativity and manufacturability.

Key Features:

- Custom Metal 3D Printing: Production of intricate and durable components for aerospace, automotive, and medical applications.

- Hybrid Manufacturing Solutions: Combining CNC machining and 3D printing for advanced design possibilities.

- Injection Molding and On-Demand Sheet Metal Fabrication

- Norck’s comprehensive offerings include injection molding and on-demand sheet metal fabrication, enabling clients to produce high-quality custom parts at scale. By leveraging its curated network, Norck delivers consistent results across all manufacturing disciplines.

Industries Served

Norck proudly serves a diverse range of industries, providing tailored solutions to meet specific sector requirements:

Norck offers specialized manufacturing solutions across various industries, delivering precision-engineered components and services tailored to each sector’s unique requirements.

Aerospace: Norck provides high-precision components that meet stringent aerospace standards, ensuring safety and reliability in critical applications.

Defense: Supplying robust and reliable parts, Norck supports mission-critical defense systems and equipment, adhering to rigorous quality and performance criteria.

Robotics: Norck creates intricate components essential for the efficient operation of robotic systems and automation technologies, enhancing performance and precision.

Automotive: Manufacturing custom parts, Norck enhances vehicle performance, durability, and safety across various automotive applications.

Medical: Producing biocompatible and precision-engineered components, Norck supports medical devices, surgical tools, and healthcare technologies, ensuring safety and efficacy.

Consumer Products: Producing high-quality, durable components, Norck serves a wide range of consumer goods, from electronics to appliances, ensuring product longevity and reliability.

Industrial: Providing durable and reliable parts, Norck supports machinery, tools, and industrial systems, ensuring operational efficiency and longevity.

Hardware: Crafting precision hardware components, Norck caters to construction, infrastructure, and various manufacturing applications, meeting specific project needs.

Electronics: Delivering custom components, Norck supports electronic devices, ensuring compatibility and performance in advanced systems.

Energy: Supplying high-performance parts, Norck serves renewable energy, oil and gas, and power generation applications, contributing to efficient energy solutions.

Norck’s tailored solutions ensure each industry’s unique requirements are met with precision and reliability, reinforcing its commitment to quality and innovation.

For more information, visit norck.com.