Part of the Creaform Metrology Suite, the Inspection module adds a new tool for rework and assembly.

Creaform, a business of AMETEK, Inc., has introduced a Laser Projection Add-on for its Inspection module, part of the Creaform Metrology Suite. This add-on, developed following Creaform’s acquisition of Virtek Vision, enhances the Inspection module by incorporating metrology-grade visual guidance for a range of applications.

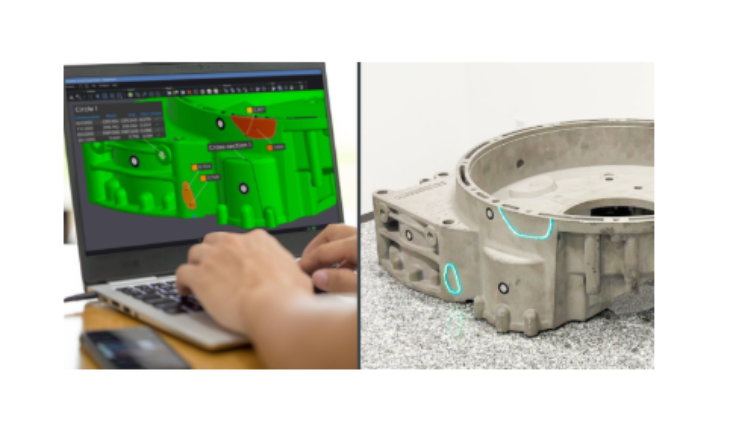

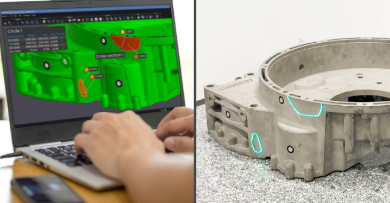

The Laser Projection Add-on allows operators to scan parts, analyze deviations from a reference model, and project critical information directly onto physical parts during key manufacturing processes, a method called Scan > Analyze > Project. The Pick and Project functionality, combined with dynamic referencing capabilities, enables real-time projection of selections made in the inspection software, simply in a single click. Since both technologies use the same positioning targets and reference structure, they integrate smoothly with existing systems.

The Laser Projection Add-on provides solutions for industries such as casting, aerospace, heavy industry, energy, and military, where precise operator guidance is required, including:

- Repair and rework of high-value parts: Operators compare scan data with CAD models and project the necessary adjustments onto the part for accurate rework, ensuring it meets specifications.

- Parts installation: A Creaform 3D scanner aligns the Virtek Vision projector to display assembly information, supporting installation processes in industries such as aerospace, heavy industry, and military.

- Raw material alignment for machining: The system projects alignment markers onto large castings or forgings, helping operators set up CNC machines efficiently while ensuring adequate material for machining.

- Composite ply inspection: The add-on supports quality control during composite layups by identifying potential defects, such as wrinkles or trapped air between layers.

For more information, visit creaform3d.com.