Infineon’s PSOC microcontrollers enable AI-driven battery optimization, enhancing safety, performance, and reliability.

MUNICH, Germany, Feb 25, 2025 – Infineon Technologies AG and Eatron extend their existing partnership for battery management solutions (BMS) in automotive to a comprehensive BMS portfolio including various industrial and consumer applications. Enabled by Infineon’s PSOC microcontrollers, this collaboration brings together the benefits of AI-powered battery optimization software and advanced power semiconductor components to create a cutting-edge solution that minimizes degradation, detects safety issues, and enhances performance and reliability of battery-powered systems.

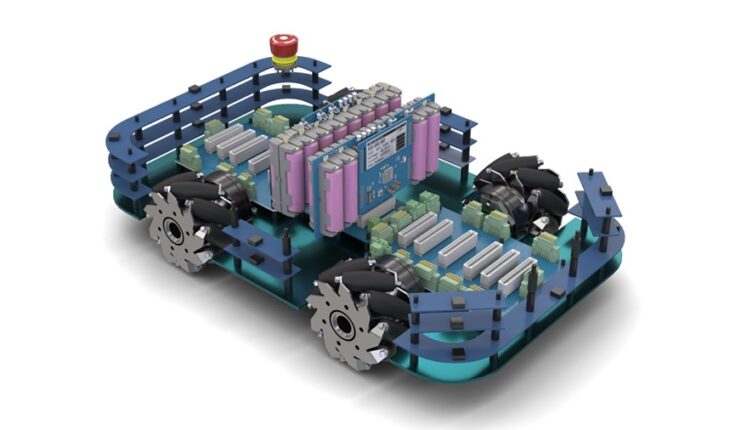

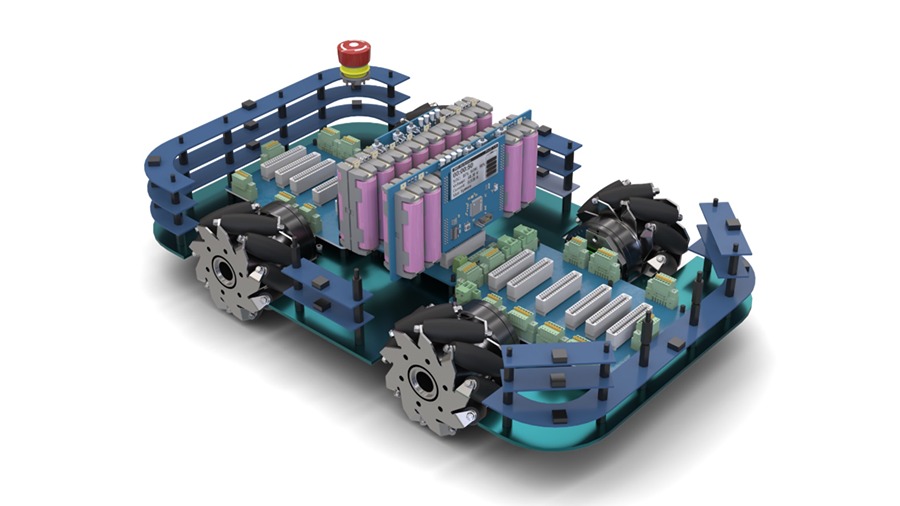

The technology integrates Eatron’s AI-powered BMS software, based on pre-trained models, featuring SOX, RUL and Safety Diagnostic, with Infineon’s components including MOSFETs for battery protection and PSOC 6 AI-based battery management system for state-of-the-art machine learning capabilities. This enables customers to unlock a range of benefits, including accurate predictions of State of Charge (SOC) of batteries, lower system cost and a faster time-to-market. The partnership addresses the growing demand for advanced battery management systems in industrial and consumer markets, such as light electric vehicles, portable electronics, energy storage systems, robotics, and power tools.

The battery management and optimization market is expanding rapidly, driven by the increasing demand for more energy usage, longer battery life, and predictive maintenance. AI plays a key role in improving battery performance making the Eatron-Infineon technology a leading solution for applications including robotics, wearables, portable medical devices, smart home devices and appliances, battery-powered IoT products, and low-power energy storage solutions.

Eatron’s software has been pre-validated and deployed on Infineon’s PSoC. It has been benchmarked on an application comprising up to 24 cells, against traditional techniques that require extensive cell characterization. The evaluation was conducted using a commercially available LG Chem INR21700 M50 cell across a broad temperature range (0–45°C), demonstrating comparable results. These findings underscore the strong value proposition of Eatron-Infineon technology.

“We’re excited to collaborate with Eatron to bring AI-powered battery optimization software to a wide range of industrial applications. Our PSOC microcontrollers, with their advanced machine learning capabilities, are the perfect fit for Eatron’s AI-powered software suite, enabling customers to unlock new levels of performance, reliability, and safety in their battery-powered systems,” said Cuauhtemoc Medina, industrial application manager at Infineon.

“We are excited to expand our partnership with Infineon, combining our Advanced SoX and predictive diagnostics software, integrated on the PSOC family to provide market-leading battery management and diagnostics in various industrial applications,” said Dr Umut Genc, CEO of Eatron.

Artificial intelligence is among Infineon’s most important growth drivers. The company’s strong position is solidified with innovations like silicon (Si) ultra-thin wafer as well as 300-millimeter gallium nitride (GaN) and the most competitive 200-millimeter silicon carbide manufacturing technology.

For more information, visit infineon.com.