Penn engineers enhance resistance to cracking by tweaking internal geometry.

Engineering requires considerable attention to detail and, for this reason, the profession tends to attract people who are particularly mindful about organization and orderliness. Of course, for every engineer with a desk so meticulously arranged that you can practically see the grid aligning every object on it, there’s the engineer whose desk looks like the day-after photos from a natural disaster.

It takes all kinds, as the platitude says, but this sentiment applies not only to engineers, but to the next generation of engineering materials as well. A team of researchers from the University of Pennsylvania have demonstrated this first-hand by showing how adding the right amount of disorder to the structure of mechanical metamaterials can more than double their resistance to cracking.

“Toughness is a limiting factor in not all, but many 3D printed mechanical metamaterials,” said professor of mechanical engineering Kevin Turner in a Penn press release. Turner is senior author of the published research, which he says shows that, “Without changing the material at all, just simply by altering the internal geometry, you can increase the toughness by 2.6 times.”

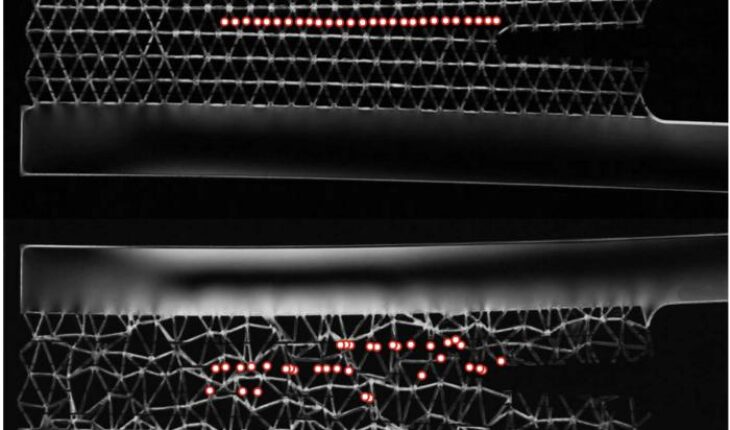

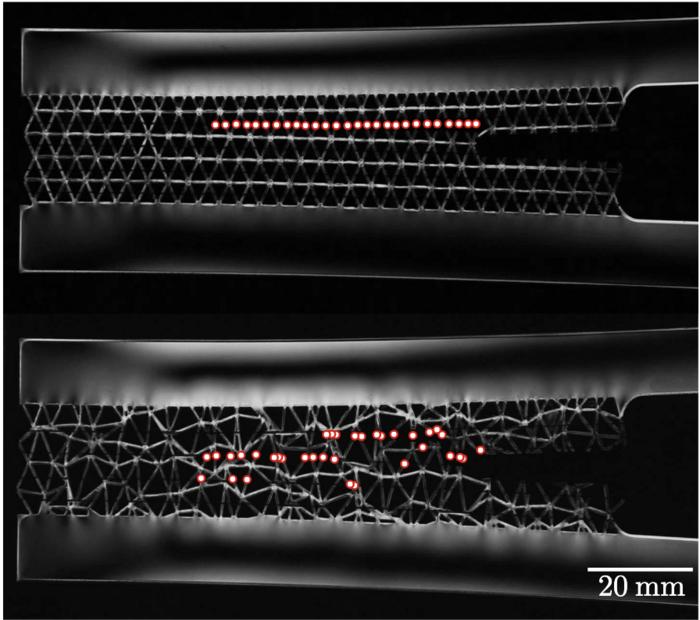

To test whether disorder makes mechanical metamaterials tougher, Turner and his colleagues performed thousands of computational mechanics simulations of numerous variations on a standard truss. In some, the triangular lattices were arranged in perfect symmetry, while in others the patterns were perturbed by shifting their connecting nodes.

“The samples that performed the best, in which it was most difficult for a crack to grow, did not consist of regular repeating patterns,” said Sage Fulco, a postdoctoral researcher at Penn and lead author, in the same release. “They had different geometry in different areas.”

The team subjected the patterns to rounds of computer simulations and created physical versions of a representative set of geometries, including both ordered geometries and those with varying levels of disorder.

When they attempted to break the materials — in the lab and in the simulations — a clear trend emerged. “There was a specific level of disorder, so that the patterns we cut into the material looked somewhat regular but not exactly symmetrical, where we were able to achieve the highest level of performance,” Fulco said.

Essentially, the disorder prevented cracks from traveling in straight lines.

In the future, the researchers hope their findings will encourage a broader exploration of disordered patterns in mechanical metamaterials and mechanical design. “We used triangles, but this work is very fundamental,” says Fulco. “Other groups can apply it to many different geometries.”

The research is published in Proceedings of the National Academy of Sciences Nexus.