AFWERX selects companies for SBIR award to fund project for additive manufacturing in aerospace.

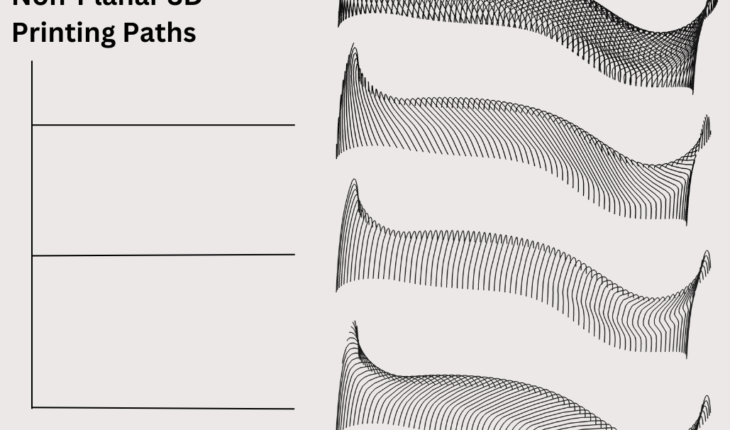

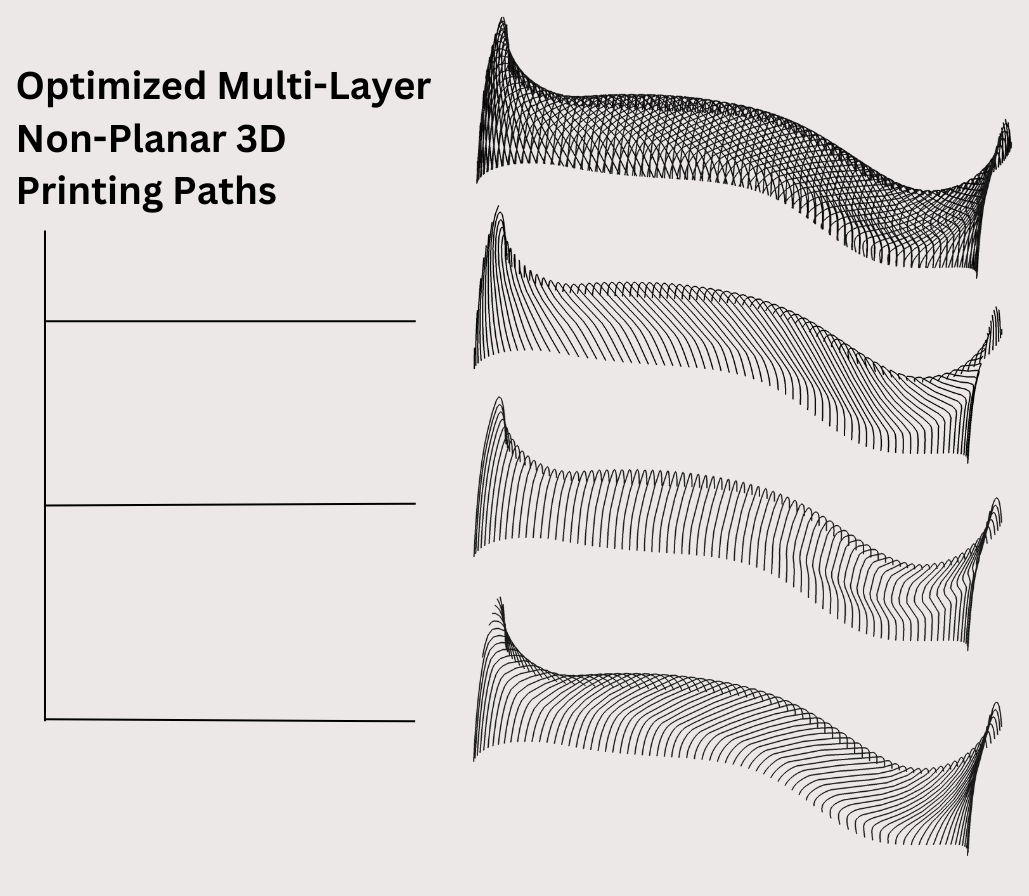

While additive manufacturing (AM) offers many advantages over more traditional subtractive methods, such as machining, it nevertheless faces many of the same challenges. Non-planar toolpaths are a prime example, guiding both printheads and cutting tools along curves or varying heights rather than restricting movement to a fixed horizontal layer. Moreover, while CNC machining has made use of non-planar toolpaths for some time – particularly in 5-axis milling – their application in additive manufacturing is still developing.

Enter AM supplier Stratasys and Novineer, a technology company specializing in generative geometry and toolpath design. Together, these two businesses are the recipients of a Small Business Innovation Research (SBIR) award from AFWERX, the innovation arm of the Department of the Air Force. The award is intended to advance non-planar toolpath optimization in AM by integrating manufacturing specifications directly into non-planar toolpaths.

“Our collaboration with Stratasys and the U.S. Air Force marks a significant leap in non-planar additive manufacturing,” said Ali Tamijani, CEO of Novineer in a press release. “By developing advanced toolpath optimization solutions, we are enabling the production of high-performance aerospace components with enhanced mechanical properties and greater manufacturing efficiency.”

Novineer has stated that it will apply its generative toolpath design technology to automate non-planar toolpath optimization for 3D printing to ensure alignment with load-bearing requirements and thereby maximize strength, stiffness and acoustic performance of additively manufactured aerospace components.

“We are excited to partner with Novineer to push the boundaries of additive manufacturing,” said James Page, vice president of software at Stratasys in the same release. “This project will help establish non-planar 3D printing as a viable, scalable solution for aerospace applications, unlocking new possibilities for mission-critical manufacturing.”

If the project proves successful, the Air Force could see smoother surface finishes, stronger parts and potentially faster printing speeds for additively manufactured aerospace components.

This is yet another example of how 3D printing is reshaping the defense landscape.