Model-based definition has many benefits, but ditching 2D drawings has even more challenges. Here’s what needs to happen for MBD to succeed.

I want to like model-based definition. My company, a manufacturer of mining equipment, has toyed with using MBD to replace 2D drawings.

But we can’t. Despite the advantages of MBD, we’ve hit obstacle after obstacle in our experiments with the technology. Each one, I believe, is solvable. To really get MBD to take off, here are the hurdles blocking manufacturers—and how I think we can collectively get around them.

How MBD works, and why we wish we could switch

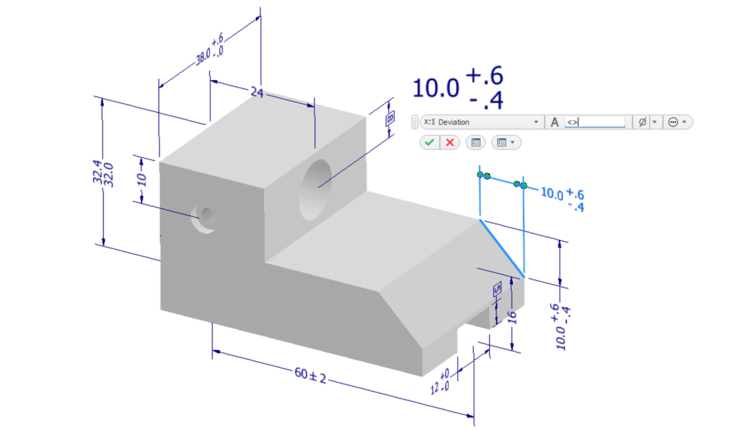

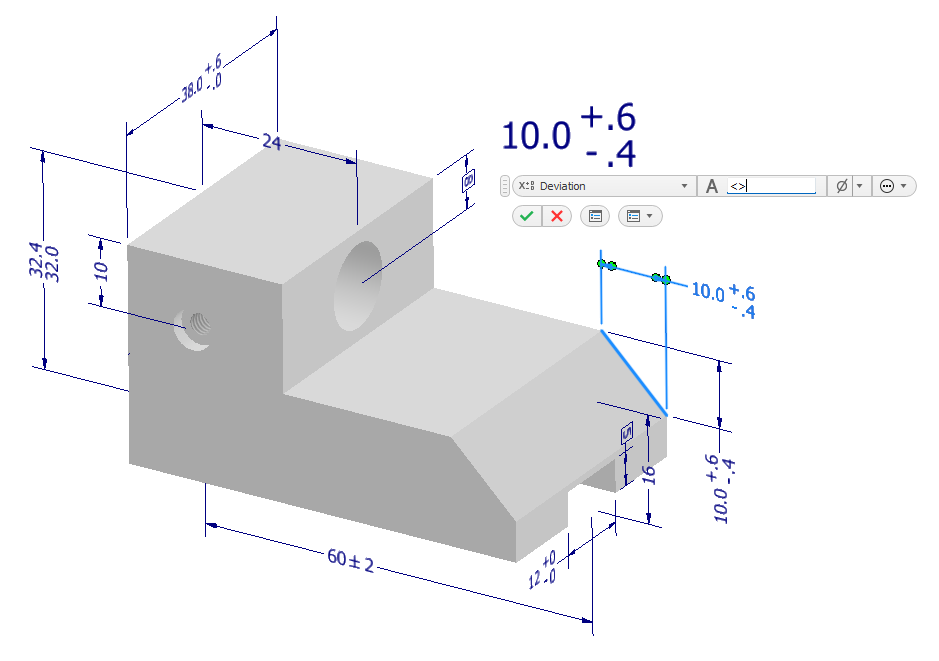

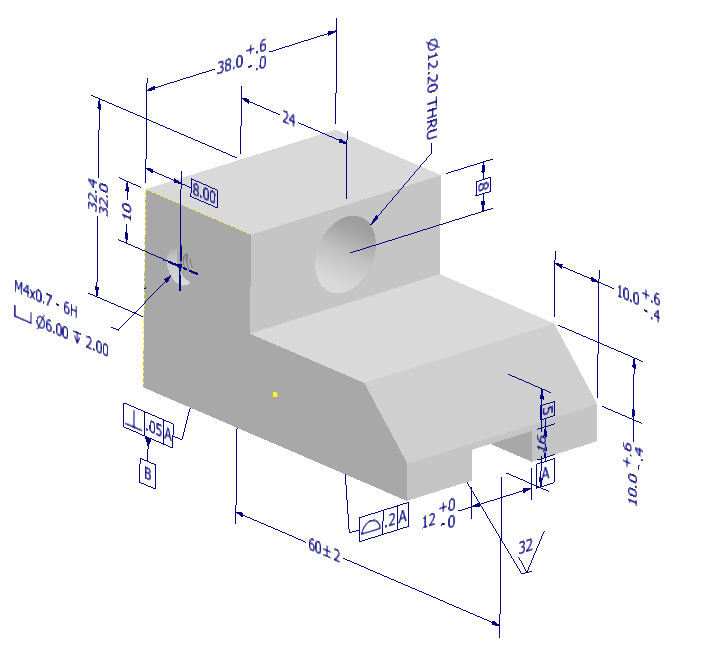

MBD is all about annotating and detailing your designs directly in 3D. All the manufacturing details that would normally be found on the 2D drawing—geometric dimensioning and tolerancing (GD&T), material specifications, surface finishes, bills of materials, assembly and manufacturing instructions, and other notes—are instead tied to the 3D model, which becomes a single source of truth. No drawings required.

MBD has a proven track record of improving communication and reducing errors. Understanding a 3D model comes naturally to most—if you can pan, zoom and rotate, every detail is right where you’d expect. 2D drawings provide the same info, but reading (not to mention creating) drawings is a learned skill that takes time and practice.

For these reasons, many manufacturing-focused CAD systems (such as Autodesk Inventor, which we use at our company) have started to implement MBD and 3D annotation features.

MBD sure seems excellent. So why are we not using it?

Problem 1: Resistance to change

The first MBD obstacle is a classic: resistance to change. Established workflows and ingrained habits mean fighting change.

The veteran staff prefer 2D drawings. Why? You can get everything you need immediately. No panning, zooming, rotating or changing views. Everything is out in front of you. And although we are paperless in the shop, you can still print a drawing when needed. It is something tangible.

Now this issue alone is no reason to shun new processes or tools. It can be overcome by selling the vision.

But what if the benefits are not that easy to see? We found that many stakeholders, like shop supervisors, don’t fully understand the benefits nor see the value of using MBD to replace 2D drawings. This can happen for any technology where the benefits are not equally apparent to all impacted. With insufficient backing, MBD adoption is challenging.

The solution is selling the vision and clearly communicating the “why.” At our company—and I’m sure we’re not alone—employee turnover is higher and we have less veterans compared to past years. Those coming out of school do not have the same skills in reading or creating 2D drawings. Moving to MBD means improved quality by making less mistakes.

Selling the vision starts with the supervisors but carries onto the shop floor. We need to ask for feedback, especially from the veterans, so they have input and feel ownership of the new process.

Problem 2: Non-existent standardization

Creating 2D drawings is an art, and the people who do it are good at it. We have long-established standards for creating 2D drawings, complemented by industry best practices, such as how to space dimensions and where to place them. This means that our 2D drawings are consistent. The shop floor knows what to expect.

To implement MBD, we need to ensure the same level of consistency and quality. Establishing standards for annotating the 3D model is therefore crucial—but challenging.

The key standards organizations (like ASME and ISO) have standards for MBD and detailing in 3D, but they’re not nearly as extensive as the 2D equivalents.

As MBD standards evolve and mature, CAD vendors need to update their tools accordingly. When detailing 2D drawings there are many workflows that lead to consistency. For example, when placing a dimension, it snaps a set distance away from the object and also a set distance away from other dimensions. This is exactly the sort of feature that CAD vendors need to implement for MBD. We need it to be easy to be consistent.

Problem 3: MBD is a time investment

Any process switch requires training. Our engineers, designers and drafters must learn how and when to use MBD. At first, engineers will be less efficient at producing MBD than in creating 2D drawings. It’s a time-consuming and frustrating changeover.

By changing to MBD, we’d be forced to make other changes as well. We use Autodesk Vault for data management, and we already have a system for version control and managing change. However, we have built our processes for distributing information to the shop using 2D drawings. Switching to 3D viewing is not significant, but it does mean deploying new software and training for the end users.

Our 2D drawings are typical manufacturing drawings. We show revisions with revision tags and change summaries in a revision table. Those on the shop floor, especially the machinists, like the revision details, as they can identify what has changed and focus only on what differs from the previous revision.

With 3D annotations—at least in Inventor—there is no way of replicating revision tables and tags. In our current setup, the shop floor has access to the Vault 2D drawing, but not to the change order. We would need to remedy this, but that entails another process change that will seem less convenient even though those affected are getting more information.

There is no easy fix for this problem. Implementing a new process like MBD is going to be an investment in time and money. In our case, we already have the technology but will need to invest time in configuring the system and training all involved.

A pilot is a good place to start. Complete a project running MBD alongside the 2D drawings. Then run another project just using MBD. You’ll learn a lot about best practices and can use the experience to develop a training plan. Then train, train, and do more training—but do it efficiently. Develop a plan. Follow the plan. And do not be afraid to adapt the plan when all does not go to plan. Training builds trust and confidence, and both lower resistance to change.

And don’t forget to take feedback along the way. People like to feel involved in change and in the decision-making process.

Problem 4: Software limitations

When rolling out something new, you want it to look as much like the old as possible. However, not all detailing and annotations can be easily replicated with 3D annotations. Some get close, but require workarounds. The workarounds are inefficient and do not always look like their traditional 2D equivalent.

For example, in Inventor, there is no way to call out a chamfer in 3D. The workaround is to add a leader and manually add the dimensions using model parameters. The end result looks like a 2D chamfer note, but it takes way more time.

So, should we switch to a different method of calling out chamfers for the sake of efficiency, or should we use the workaround to ensure consistency with the 2D drawings? Questions like these can pileup and increase resistance to change.

Step one in tackling this problem is to pressure CAD vendors to improve the product. Between beta testing programs, community forums, resellers, and technical support, there are many avenues to express your concerns and provide feedback. You might be a single voice, but you’re likely not the only one with a given problem.

Next is to look for help on how to deal with limitations. Look to the community and involve your CAD reseller, many of whom have on-staff expertise. You’ll have to incorporate those limitations into your best practices. In our case, we must decide what is acceptable and what requires workarounds to resemble the 2D equivalent.

Problem 5: Supplier compatibility

Ensuring smooth and reliable data exchange between our company and its suppliers can be challenging. Not all our suppliers can handle 3D models or interpret MBD data.

For example, the vendors that cut plate for us need DXFs. DXFs are 2D drawings. So, should we not implement MBD for the plate and continue with 2D drawings?

If we were to implement MBD, we would use MBD for the components we build and assemble, and continue to create 2D drawings for subcontracted operations. It’s not ideal, but it would only affect engineering. Our production team would get the benefits of MBD, and our vendors would continue receiving data with which they can work.

We could then explore current software capabilities to generate DXFs from the 3D model, and if needed we could customize the application to produce the desired results.

Problem 6: What about the old drawings?

We have a significant investment in 2D: Thousands of drawings spanning more than forty years, engineering-approved and ready for shop consumption. If we switch to 3D, what do we do with the existing 2D? Do we maintain two systems? Or do we start a massive investment in switching all existing drawings to MBD?

This is eerily similar to when we switched from designing in 2D with AutoCAD to designing in 3D with Inventor. If only MDB had been an option back then!

The solution, as with switching to 3D CAD, is to leave the existing drawings. We would detail everything new using MBD. During a revision, an effort-vs-reward analysis would decide if we should update the existing 2D drawing or if the change is extensive enough to justify moving the design to MBD.

For selected equipment we could consider offloading the conversion to a third party—someone experienced in MBD who could convert the 2D drawings more efficiently (i.e., cheaper).

Is MBD right for you?

It’s important to assess your organization’s needs carefully before making a process change. MBD implementation is no different.

Our 2D legacy and vendor requirements make it challenging for us to justify the costs of transitioning to MBD. The effort must at least equal the reward; right now, it does not. However, we recognize the potential benefits of MBD and will continue to monitor software advancements and industry changes—perhaps in the future the cost and reward calculus will change.