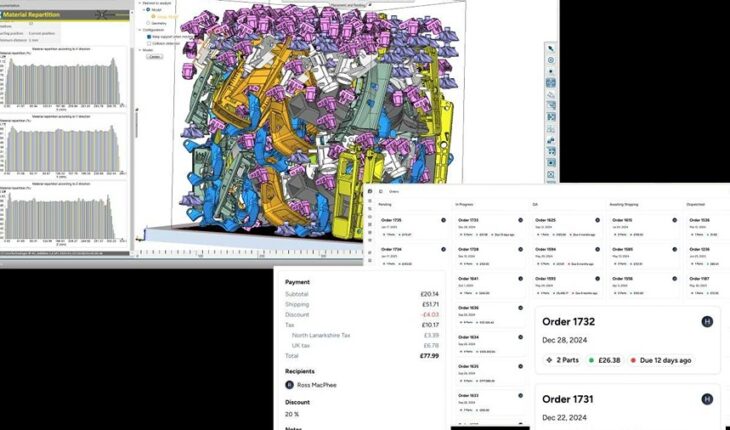

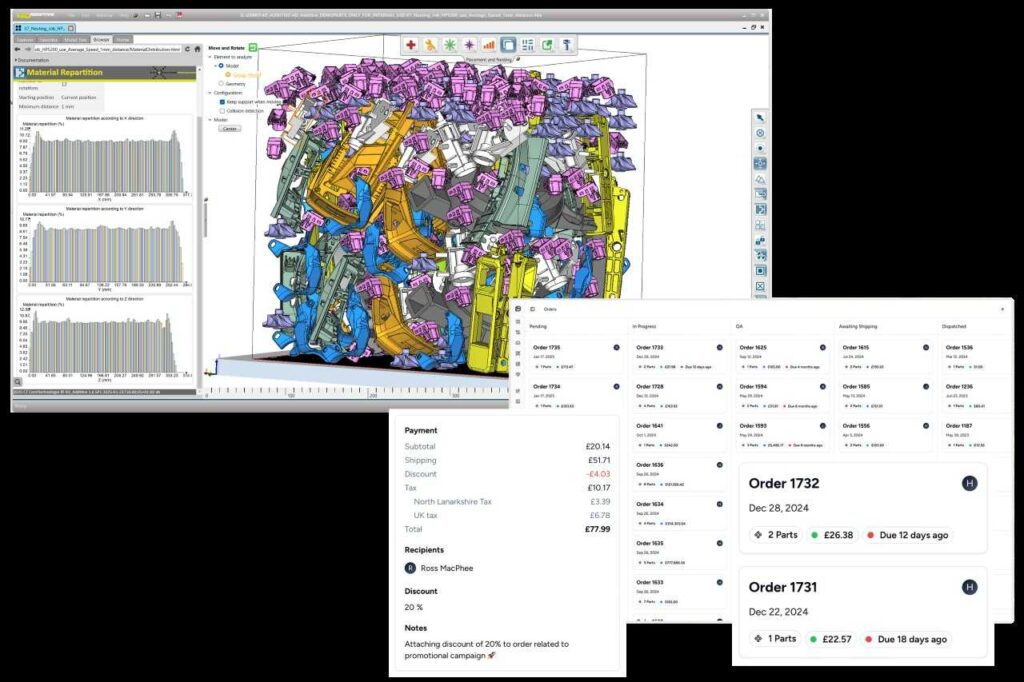

Phasio’s software integrates with CoreTechnologie’s 4D_Additive for automated additive manufacturing.

CoreTechnologie and Phasio are joining forces. The new partners are introducing an automated solution for users of SLS (selective laser sintering) and MJF (multi jet fusion) technologies.

The integration of Phasio’s advanced software with CoreTechnologie’s 4D_Additive enables seamless, fully automated workflows in additive manufacturing. Production management, nesting and real-time updates are integrated into a single, optimised process. The collaboration between the two software manufacturers increases efficiency, eliminates human error and accelerates the scaling of production processes, revolutionising SLS and MJF workflows.

Advantages of the Integrated Solution

Phasio’s AI-powered platform enables fast and accurate quotation generation, optimised production planning and quality monitoring to simplify overall production management. 4D_Additive’s advanced, AI-based nesting tools ensure optimal utilisation of machine capacity, saving time and resources. Real-time updates in Phasio minimise manual intervention, reduce errors and increase operational reliability.

Scalability for Additive Manufacturing

The integrated solution supports production companies in scaling their additive manufacturing while simultaneously optimising cost efficiency and quality standards.

By combining the robust production management capabilities of Phasio and the innovative nesting capabilities of 4D_Additive, this partnership provides a sophisticated end-to-end solution for additive manufacturing facilities. This enables control over production processes while automating repetitive tasks. This saves time and process costs and ensures consistent quality and reliable data management throughout the entire workflow.

The collaboration between Phasio and CoreTechnologie creates new opportunities for innovation and scaling of additive manufacturing.

For more information, visit coretechnologie.com.