Production of parts on demand could reduce delivery times by as much as 75%.

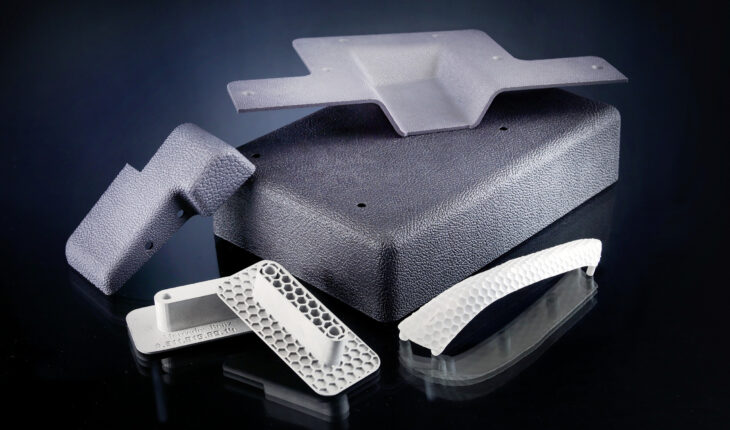

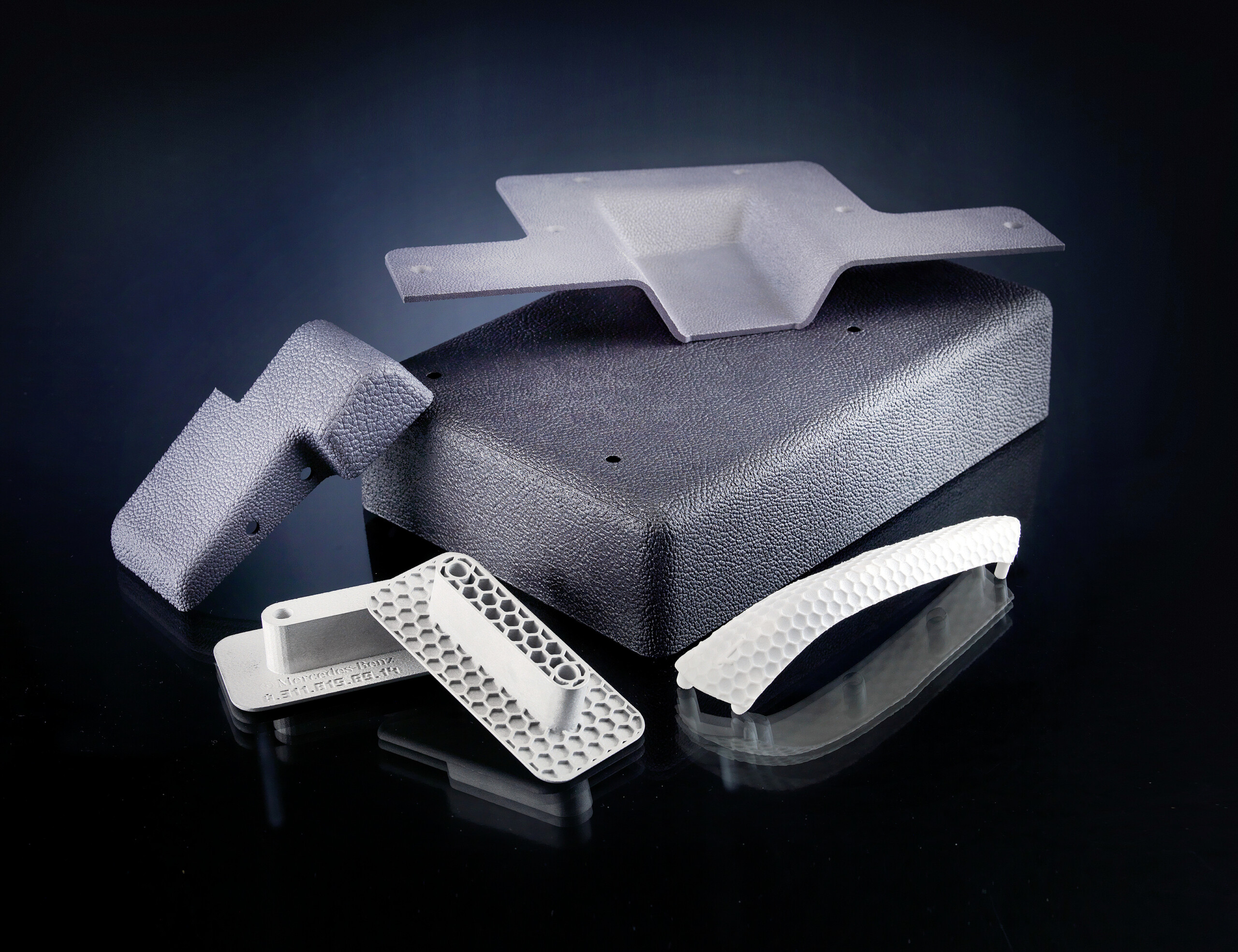

Just under 40,000 bus spare parts are already 3D printable today. Some of these are already available only as 3D printed spare parts after having undergone the relevant digitization steps, approval processes and numerous product tests.

One of the underappreciated applications for 3D printing technology is on-demand production of spare parts, particularly in the automotive industry. While we may never see automakers churning out fleets of 3D printed cars, using additive manufacturing (AM) to ameliorate supply chain issues is growing in popularity.

Case in point, 3D Systems and Daimler Truck | Daimler Buses are now collaborating along with Oqton and Wibu-Systems on enabling the commercial vehicle manufacturer’s certified AM partners to 3D print spare parts. These include underhood and cabin interior applications, along with pins, covers and inserts. According to 3D Systems, this capability will reduce delivery times for spare parts by up to 75%.

“We are very pleased that we are expanding the revolutionary solution with 3D Systems, one of the world’s leading 3D printer manufacturers, and realizing our vision for decentralized spare parts production,” said Ralf Anderhofstadt, head of center of competence additive manufacturing for Daimler Truck and Buses in a 3D Systems press release. “The Digital Rights Management enables us to shorten service times through decentralized production in order to further maximize productivity and revenue for commercial vehicle companies. In addition, the sensible use of industrial 3D printing results in reducing the complexity in the supply chains. Through our collaboration with 3D Systems, Oqton and Wibu-Systems, we are setting another important milestone in the expansion of decentralized 3D printing production.”

Bus and motorcoach companies or service bureaus can join Daimler Buses’ network of 3D printing certified partners by purchasing a license for 3DXpert AM software through the company’s Omniplus 3D-Printing License eShop. The prepare and print license enables the customer or service partner to decrypt the design files for the parts needed for a specific repair job and only produce the exact quantity needed.

Currently, the solution is designed to 3D print parts on 3D Systems’ SLS 380 but Daimler Buses anticipates that service bureaus will eventually be able to connect any 3D Systems’ polymer or metal 3D printer to the solution.

“By commercializing this digital service solution, Daimler Buses is not only adopting a new technology; they’re fundamentally reshaping the supply chain for greater resilience and efficiency,” said Jaime Garcia, additive solutions manager – automotive and commercial transportation at 3D Systems in the same release. “Our SLS 380 is a high throughput additive manufacturing solution with unprecedented levels of throughput, consistency, performance, and yield. I’m pleased that this is the first 3D Systems technology to be integrated into Daimler Buses’ workflow. I look forward to seeing how the capabilities grow as we add other polymer as well as metal 3D printers in the future.”