MIT engineers combine two-photon polymerization with digital light processing to create a droplet-emitting electrospray engine for small satellites.

When it comes to in-space manufacturing, 3D printing is the preferred approach by far, and for good reason. Imagine trying to run a CNC machine tool in microgravity! Picture the fine sprays of chips and globs coolant floating about, not to mention the effect gyroscopic forces would have on the spacecraft in which the tool is installed.

So, if additive manufacturing (AM) is the way to go in zero-g, the natural question to ask is: What should we use it for?

A team of MIT engineers have just provided one answer: 3D printed electrospray engines.

These thrusters apply an electric field to a conductive liquid to generate a high-speed jet of droplets that can propel small spacecraft, such as satellites. However, because the thrust they generate is relatively small, electrospray engines typically operate in parallel as arrays, and manufacturing these arrays is both expensive and time-consuming, requiring semiconductor cleanroom fabrication.

“Using semiconductor manufacturing doesn’t match up with the idea of low-cost access to space. We want to democratize space hardware. In this work, we are proposing a way to make high-performance hardware with manufacturing techniques that are available to more players,” said Luis Fernando Velásquez-García in a press release. Velásquez-García is a principal research scientist in MIT’s Microsystems Technology Laboratories and senior author of a paper describing the thrusters.

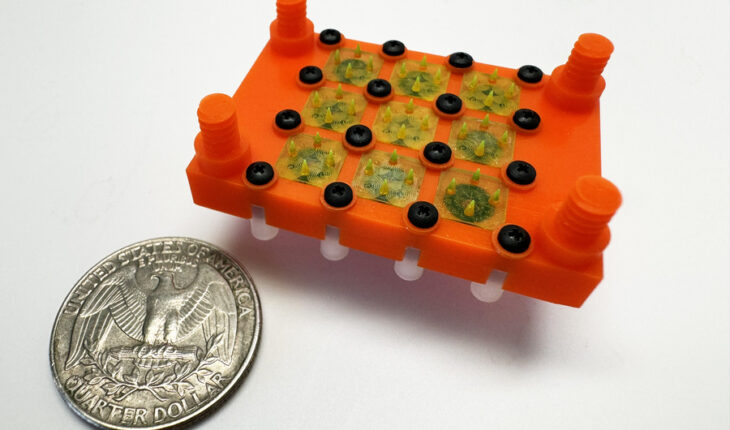

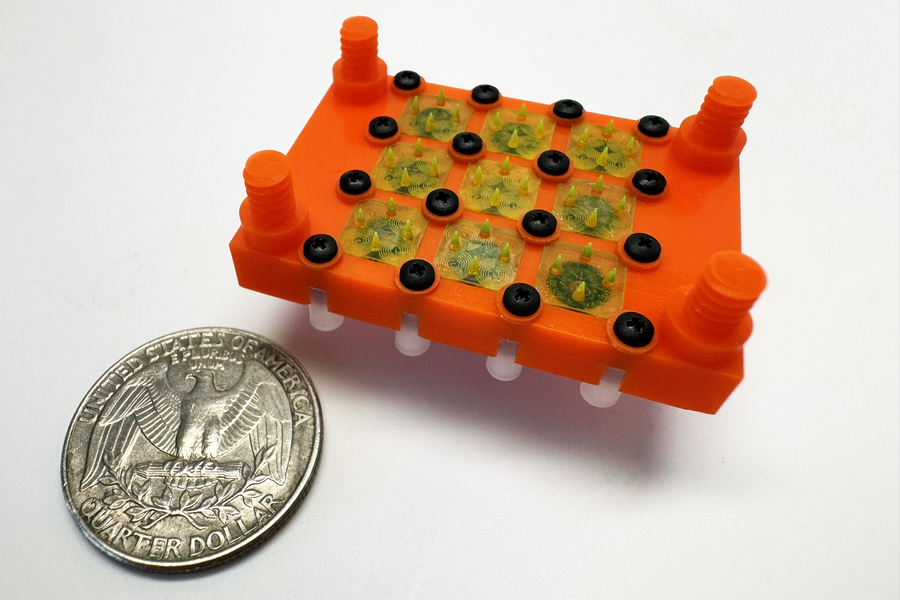

The MIT electrospray engine consists of eight emitter modules, each of which contains an array of four individual emitters that operate in unison.

“Using a one-size-fits-all fabrication approach doesn’t work because these subsystems are at different scales. Our key insight was to blend additive manufacturing methods to achieve the desired outcomes, then come up with a way to interface everything so the parts work together as efficiently as possible,” said Velásquez-García.

The researchers combined two-photon polymerization (2PP) with digital light processing to produce their design, with the former fabricating the emitter modules while the latter produced the manifold block which houses them and supplies them with propellant.

After testing to ensure compatibility between the printed materials and the liquid propellant, the researchers concluded that their prototype was able to generate thrust more efficiently than larger, more expensive chemical rockets in addition to outperforming existing electrospray engine designs. Further researcher will endeavor to demonstrate a satellite that utilizes a 3D printed electrospray engine during operation and for deorbiting.

The research is published in the journal Advanced Science.